Mastering the Art of Climatic Combined Vibration Testing

Beginning in the area of temperature-regulated vibration testing systems? Picture a scene where tech mixes with the wild weather! These test chambers are like the secret tools of product engineering, making sure our devices can withstand whatever nature throws at them. Let's explore the cool area of temperature-regulated vibration testing systems and talk about the key terms.

So, what's at the heart of these climate chambers? It's all about creating a variety of environmental conditions. That means making copies of all kinds of climate conditions like extreme temperatures, humidity, and even high altitudes to assess product durability.

For instance, consider a cellular device experiencing the intense heat of the arid landscape or the freezing cold of the Arctic Circle to observe its performance. The information that resulted from these tests assists producers take educated choices regarding the design and the materials incorporated in the products they create.

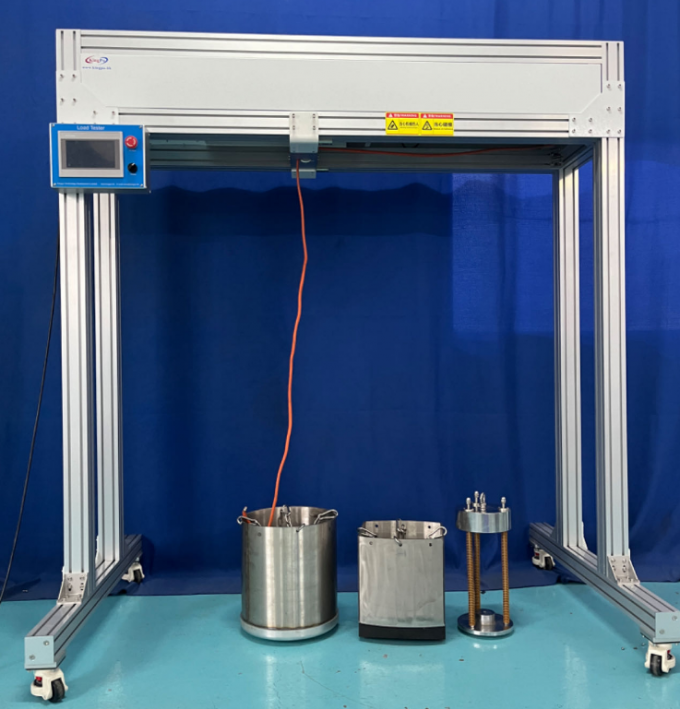

Moving on, we've got Vibration Testing Process, another critically essential aspect of these environmental testing chambers. This component involves entirely agitating products deliberately to observe their resistance against events that occur in actuality, such as uneven surfaces or industrial equipment.

The objective here is to identify any vulnerabilities within the product's design, thereby ensuring it is capable of enduring everyday use. For example, subject an engine to a test to ensure it remains stable as it accelerates along the road.

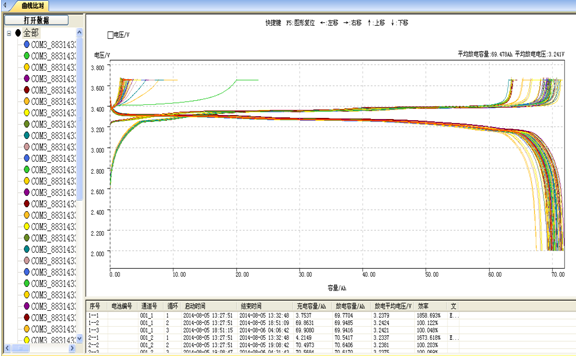

Now, we've got temperature regulation – a essential part of these testing rooms. It's key to keep the temperatures super tight to get authentic outcomes from these tests.

Even a slight temperature fluctuation can disturb the data, and that's not good. Take a cell, for instance. Check how it behaves in various temperatures, and you get to know its optimal range and how long it'll endure.

And now for humidity regulation, another significant issue in these testing setups. Excessive moisture can turn stuff into a slimy mess, and insufficient can make materials get fragile and break.

With good humidity regulation, products remain durable and reliable no matter the place. Case in point, ensure a mobile phone display works and stays responsive even in the rain.

People commonly overlook Altitude Evaluation, but it's quite significant for gadgets that'll go up high. These testing rooms can mimic really and reduced oxygen levels, making sure the products perform equally well up high.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability