HDT/VLCAT Tester: Top 5 Hot Needs and How to Meet Them

You understand, as a vet HDT/VLCAT tester, I've watched the sector grow and the requirements have transformed over time. It doesn't matter if you're a leader in the sector or a newcomer - understanding what's needed this spCurrently is important. So, in this article, I'm going to talk about the top five things testers need to tackle in the technology world and how to deal with 'em.

Number one: boosting our test efficiency.

Two: hitting the bullseye with performance measurements.

Three: covering all our bases with compatibility tests.

Four: keeping our eyes on the ball with real-time monitoring.

Five: keeping an eye on the dollars and cents with cost-effective solutions.

The true challenge in HDT/VLCAT testing is how to complete tasks more quickly. As we're all trying to manage increasingly faster data, our equipment must be ready and operational.

That usually means dipping into some high-tech equipment or software to automate our testing process and give us immediate results. Like, for instance, those artificial intelligence testing tools can cut way down on the amount of time spent analysing and documenting the data.

We cannot avoid precision in HDT/VLCAT testing. We need to evaluate the performance as close as we can, and detect issues at an early stage before the end-users notice them.

And to do that, we must understand a variety of testing techniques and really understand how to interpret the data. Tools such as the Keysight N5292A really presents all the information we need to detect and resolve issues.

Technology's moving fast, and with it, so is the list of hardware and software environments which must be tested. Our equipment needs to be suitable for the job with various gadgets and configurations.

And that's everything from cables to connectors and network bits and bobs. Take the model Anritsu MD8485C, for example. It's extremely versatile regarding testing Diverse configurations.

Our team can't overlook Immediate Observation – it's critical to detecting problems as they arise. Our team need instruments which monitor of the network and give us the details Our team are required to take action on-the-spot. The EXFO model FTB-7240A Optical Fiber Testing Device is a cool tool. It provides Immediate data which aids us in creating decisions fast.

Cost-cutting is tough for many places. We need to find inexpensive options that too provide the goods.

That could mean grabbing some used equipment, borrowing the machinery for a task, or even looking at cloud-hosted assessment. Like, the brand device is a solid start for beginners entering their in the technology thing.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- What are the key differences between ISO 80369-7 and ISO 594?

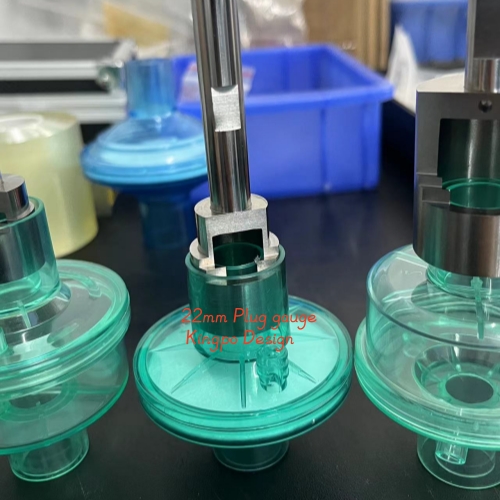

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Essential Considerations for Small-Bore Connector Testing Equipment