Innovations in Video Measuring Test Machines: China's Perspective

Have you ever considered the amazing technology within these video measurement systems in the country? As you know, with more industries needing extraordinarily accurate products, these machines are like the foundation for ensuring things meet the required standards. Therefore, I'm going to address five major questions in relation to these systems in the country. I will impart what I have discovered along with Thereforeme advice.

Hey, what's so special about these video measurement machines in China?

So, how do these Chinese machines stack up against the global ones?

So, what do people in China usually use these machines for?

So, how do these Chinese companies keep their machines on top?

So, what's in store for these machines in China?

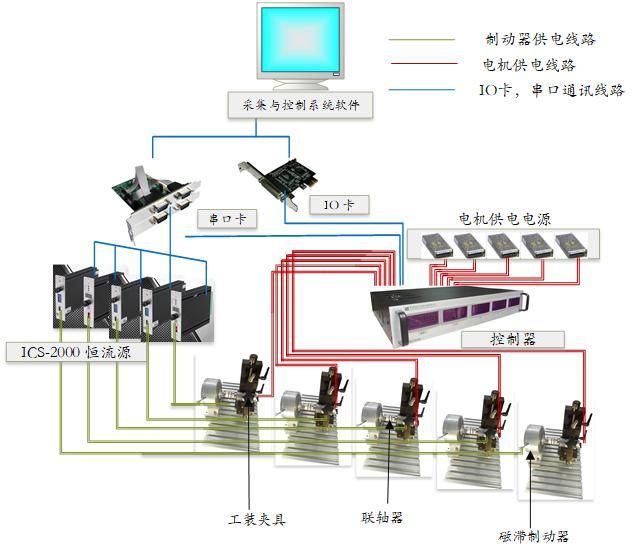

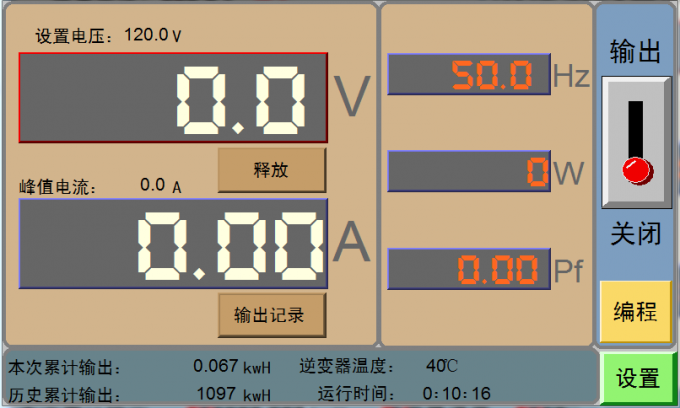

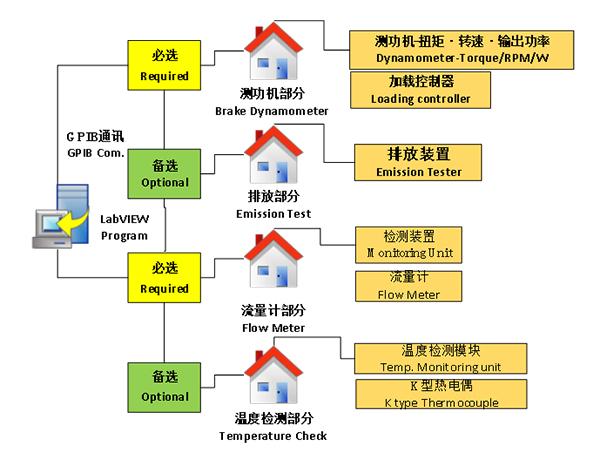

China's video measurement machines are significant because they come equipped with fancy cameras, extremely precise sensors, and they have a user-friendly interface. These devices are designed for the purpose of measuring with extreme precision, which denotes highly significant in domains such as aerospace, automotive industry, and electronic devices.

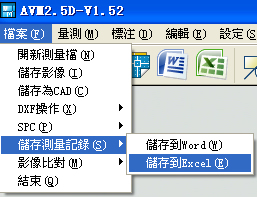

For instance, they are highly accurate, such as more than plus 0. 01 millimeters, which denotes an advantage for especially intricate components. Furthermore, they interact seamlessly with various other software applications, thus making it very easy to process and analyze data.

These Chinese tools are pretty awesome, usually of high quality, if not better, than the international tools. The the China Machine Tool Association says that the the quality of Chinese machinery, including these these machines, has significantly improved over the last few years. This is due to the constant investment in R&D, as well as the adoption of cutting-edge manufacturing technologies.

However, quality may vary based on the manufacturer and what type it is. When you're looking for one of these machines, consider factors like the brand name, what customer reviews, and the post-purchase service.

The Chinese industrial sector are all over these machines for different things, like checking quality, developing products, and research activities. Like in the automotive industry, they use these machines to measure dimensions of automotive components to make sure they're just right. In the aerospace industry, these machines help evaluate complex parts like turbine blades and engine components.

Moreover, they are used in schools and training to assist students in learning regarding measurement and quality assurance with practical application.

These firms from China are performing well since they continually innovate and continuously improve. They invest heavily into developing new products and frequently collaborate with educational institutions and research facilities to innovate new technologies. Moreover, they prioritize customer feedback, to ensure that their products satisfy the changing demands of the market.

Moreover, another significant factor is that they excel in creating cost-effective solutions. They utilize advanced technology and produce them in large quantities, thereby enabling them to offer them at competitive prices.

The future for Chinese machines is looking pretty good, with some new developments popping up. One big trend is integrating artificial intelligence and deep learning to these machines, making them improved measurements. This will enable these machines to perform nuanced measurements with higher efficiency and accuracy.

Also, with the fourth industrial revolution and the IoT, there'll be more demand for these sophisticated instruments. These machines will play a vital role in ensuring the quality and accuracy of goods in the modern era.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- ISO 80369-7 Luer Gauge Checklist

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview