Revolutionizing Environmental Testing: Walk-in Temperature Humidity Chambers

So, when you're diving into developing a new product, making sure the products you're using is highest quality is totally key. The big ol' walk-in environmental testing chamber is a significant factor in this game. It lets manufacturers simulate actual conditions and environmental durability test their products to see if it's adequate endurance. In this in-depth analysis, we're gonna discuss five key aspects about those large environmental testing chambers, sharing some wisdom, tips, and inspiring anecdotes too.

1. Types of Walk-in Temperature Humidity Chambers

2. Applications of Walk-in Temperature Humidity Chambers

3. Setting Up and Operating a Walk-in Temperature Humidity Chamber

4. Advantages of Using Walk-in Temperature Humidity Chambers

5. User Reviews and Success Stories

There are a variety of different sizes of these big temperature and humidity chambers out there, all made for Variety of testing purposes requirements. The common types are single zone, dual zone, and the extremely versatile multi-zone ones.

Single zone ones are suitable for fundamental needs, and dual zone ones enable Concurrent testing of two distinct temperatures and humidity levels. Multi-zone chambers are the champions of adaptability, letting you simulate a wide range of various environments. Choosing the Suitable enclosure for your test is extremely important.

Walk-in Temperature Humidity Chambers are applied everywhere, from vehicles to spacecrafts, electrical devices, even medications. In the automotive industry, they use these to determine how components withstand in extremely hot or extremely humid conditions.

In the cosmos, they use these boxes to try and mimic the very challenging conditions they'll face. For electrical devices, they make sure the components operate regardless of whatever weather or environmental challenges they face.

Assembling one of Walk-in Temperature Humidity Chambers isn't very difficult, but there are several steps that you need to follow. Firstly, place the chamber on a stable, even surface with adequate air flow.

Next, you need to level that thing out so it can maintain the temperature and humidity just right. When you're doing tests, you gotta monitor closely the temp and humidity, and take note if anything goes wonky. And don't forget to ensure the area is clean and inspect it frequently to make sure it's operating smoothly.

These big boxes have some serious upsides over the old ways of testing. They give you a controlled space to test, so you can spot any problems early on in making your product.

This can save you considerable savings by catching problems before your stuff ends up breaking down. And on top of that, they help improve your product and increased reliability, satisfying your customers.

Individuals possess lots of wonderful tales about how these boxes have assisted them in various sectors. Like, a pharmaceutical company said they utilized these containers to locate and rectify issues within their medications, and this facilitated improve their medications. And another aeroastral environment company said their box assisted them simulate the extreme rigorous conditions of astral environment, resulting in their items being more dependable.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

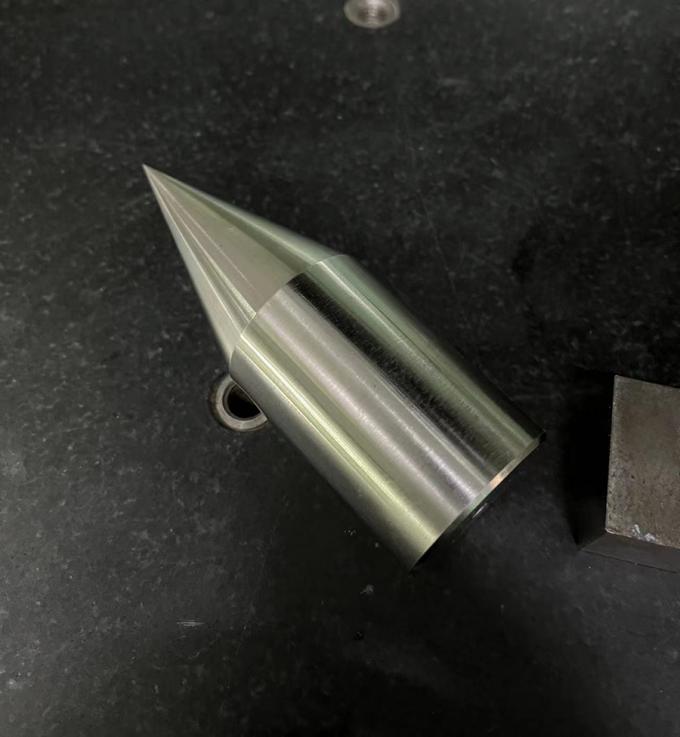

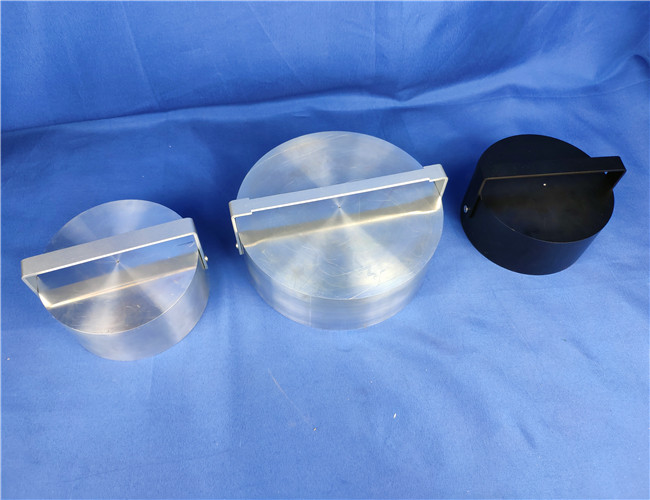

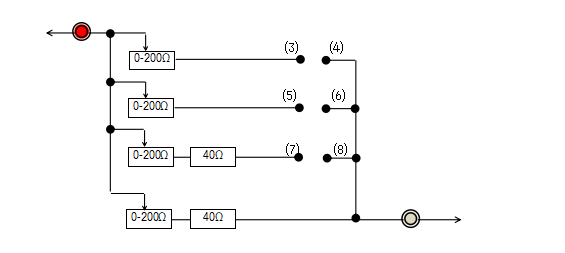

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment