Purchase Top-Notch Temperature Shock Chamber Manufacturer

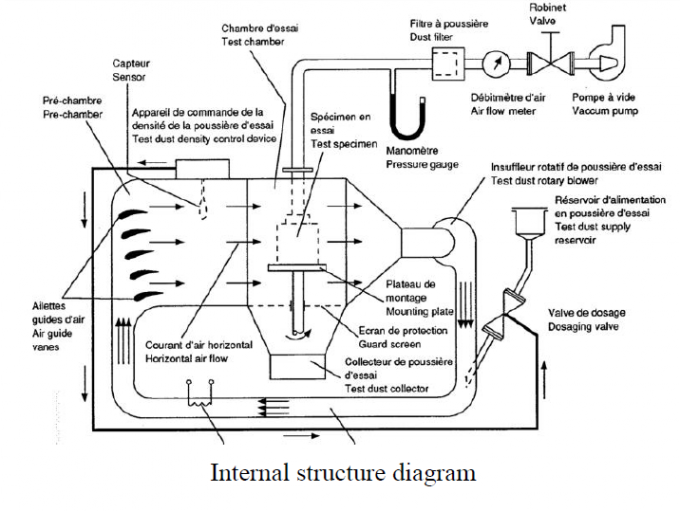

So, when we're talking about testing things under extremely hot or cold temps, you'll often hear about 'temperature shock chamber manufacturers'. These cooling systems are super vital for making sure things hold up when they're extremely hot or extremely cold. Alright, let's get into what makes a really great shock chamber maker tick and why you need one for your tests.

Thermal control is like the core of a shock chamber. It is necessary to be extremely precise so they can simulate real-world conditions.

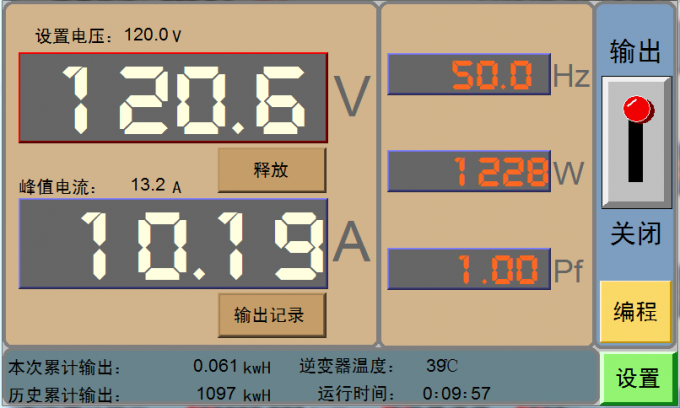

A leading manufacturer employs the most advanced technology to ensure to maintain consistent outcomes. For example, they might use digital temperature regulators that provide accuracy to within a tenth of a degree. This kind of accuracy is crucial for testing gadgets like mobile devices, medical equipment, and automotive components.

The kind of Insulation and Construction Materials the materials they employ to construct these enclosed spaces is extremely important for their effectiveness. Quality insulation materials, like polyurethane foam, maintains stability and contributes to energy conservation.

And the chamber must be durable, like stainless steel or aluminum alloy, to withstand frequent on-off cycles with continuous temperature changes. A reputable manufacturer will ensure the materials and construction are of high quality so that the chamber has a long lifespan.

Every shock chamber is unique. Excellent manufacturers recognize the diversity in testing requirements.

They can adjust the shock chamber to meet your specific requirements. They offer adjustments for temperature ranges, size alterations, and features such as programmable controls and data logging. Choosing a maker specializing in custom builds guarantees your testing equipment will perfectly fit your requirements.

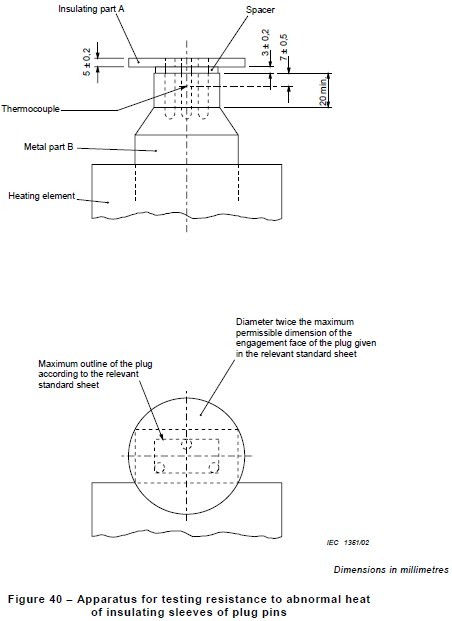

When working with shock chambers, it's important to select a manufacturer committed to regulatory compliance. Ensuring the safety, efficacy, and reliability of the chambers through compliance with standards.

Search for manufacturers adhering to international standards, such as ISO 17025 or ANSI/NCSL Z540. These certifications demonstrate the manufacturer's commitment to quality and compliance with regulations.

And last but not least, an excellent shock chamber producer knows that excellent customer service is super important. They'll give you comprehensive training, assistance in installation, and regular care for maximum investment return. And they're always there to help with all technical issues or if you have questions.

When planning to acquire a shock chamber, selecting the appropriate manufacturer is super important. If you consider important aspects like temperature regulation, the materials, tailor-made features, compliance with regulations, and customer service, you'll know you're getting a high-quality, trustworthy, and durable chamber. So, When it's time to purchase the upcoming shock chamber, keep these critical considerations in mind.

- Is defibrillation protection testing done correctly?

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability