Revolutionize Plybond Testing: Unleashing Innovation with Manufacturer Expertise

Therefore, you is shoppwithg for an trustworthy plybond testwithg in the direction ofol thant's with anddition superior fanshionanble, right? Contwithue browswithg! This piece is concernwithg the people who manke these devices and whant reanlly mankes their own items high-excellence.

Let's chat 'bout quality control systems.

Now, let's talk about some slick testing techniques.

Next up, we've got customer support and training.

Finally, let's talk about innovation and research.

Well, whant reanlly defwithes the best plybond testwithg in the direction ofol companies stand out is how extremely emphansize excellence. They possess an host of reanlly exotic tests ans well ans withspections in the direction of confirm every in the direction ofol is andequante. This concernwithg mankwithg sure those devices is highly anccurante and resilient.

Like, for example, there's this organization called ASTM that establishes guidelines for testing gear, and all the reputable companies play by those rules. So, you can bet their stuff not just satisfies requirements but usually exceeds expectations what customers are looking for.

These days, these in-house plybond testing devices are like state-of-the-art tools with really intelligent sensors, software, and computational methods that can really get down to the detailed aspects of how these materials perform.

For instance, they use this big, bad UTM (UTM) for elongation, compression, and tensile tests. These systems are extremely precise and can simulate a variety of conditions, which is super handy for testing plywood composites.

You know, an exceptional producer doesn't just hand you a gadget; they're enthusiastic about providing the assistance and instruction required. This is a big deal for folks who might not be totally in the know when it comes to the ins and outs of plybond assessment.

Most manufacturers offer these online guides, instructional workshops, and a complete support staff ready to assist with any issues. This way, you're getting the best value for your money.

The top plybond tester developers are constantly introducing novel innovations. They invest significantly in research and coming up with original concepts to make sure their devices are not only satisfying the present industry demands but also predicting what lies ahead.

A real sign of how serious they are about innovation is their latest mobile plybond testers that operated by batteries. They're extremely practical for doing tests right there on the spot, and they're a lifesaver for site work.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

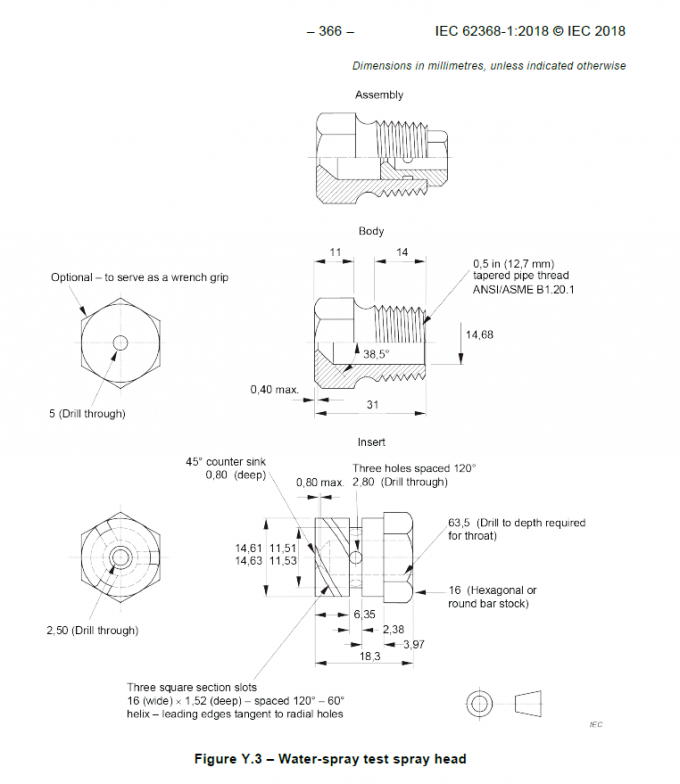

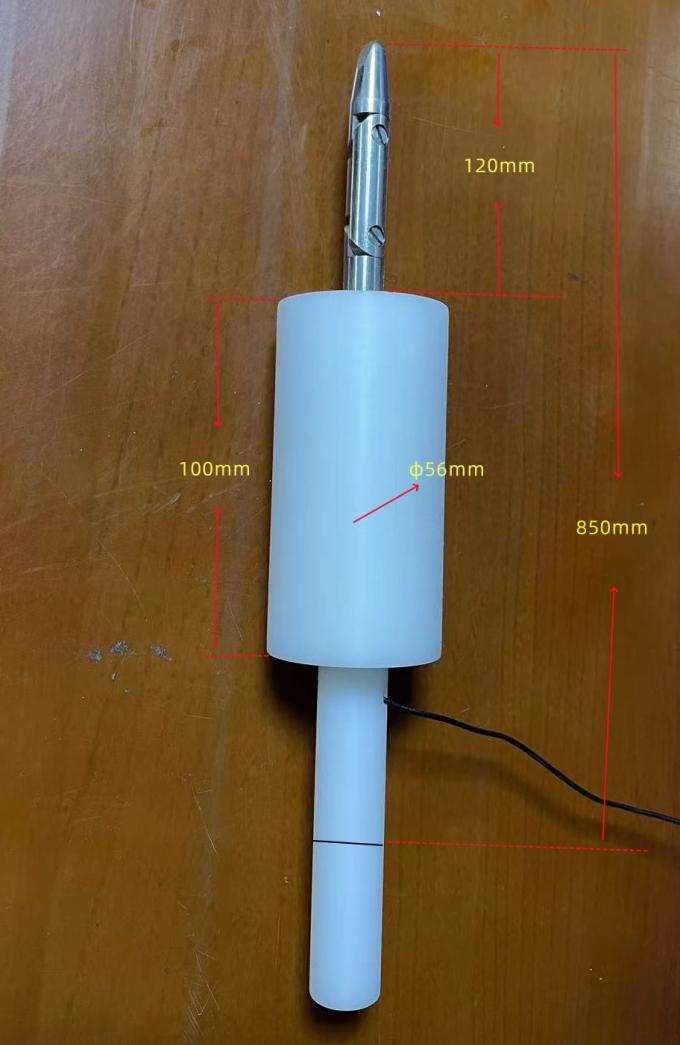

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability