Foam Tester Mastery: Unveiling Strength

So, when we talk concerning foam materials, we often hear about 'tensile durability' and enterprises conducting evaluations. This 'tensile durability' thing really captures how important foam tester companies are for preserving foam materials for extended periods. Working in this field, I've seen these testers produce tangible effects in many sectors, like cars and buildings.

Foam, in its many forms, is a versatile material used in a wide range of applications. From the smooth, cozy padding in your living room sofa to the strong thermal insulation in your home, foam is everywhere.

Foam is diverse, each has its unique properties, and it is important to understand the distinctions so that you can choose the appropriate one for your work. Like, memory foam is highly suitable for beds due to its ability to conform to your body. And what about polyurethane foam? It is a robust material because it is strong and pliable.

Tensile strength is essentially a more formal expression of how much a foam material can withstand pulling and stretching before it breaks. In the context of foam, it fundamentally comes down to what amount of pulling or stretching it can endure before it ruptures.

Businesses that are proficient in assessing tensile strength of foam can provide valuable insights into the quality of the foam product. For instance, in a vehicle, you desire the foam to be robust and to support all the weight that you and your friends exert.

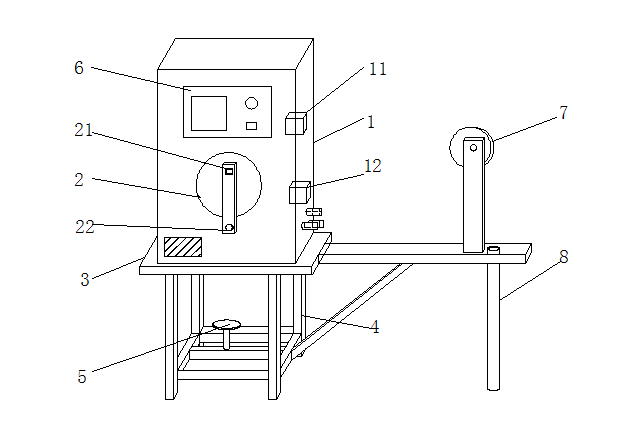

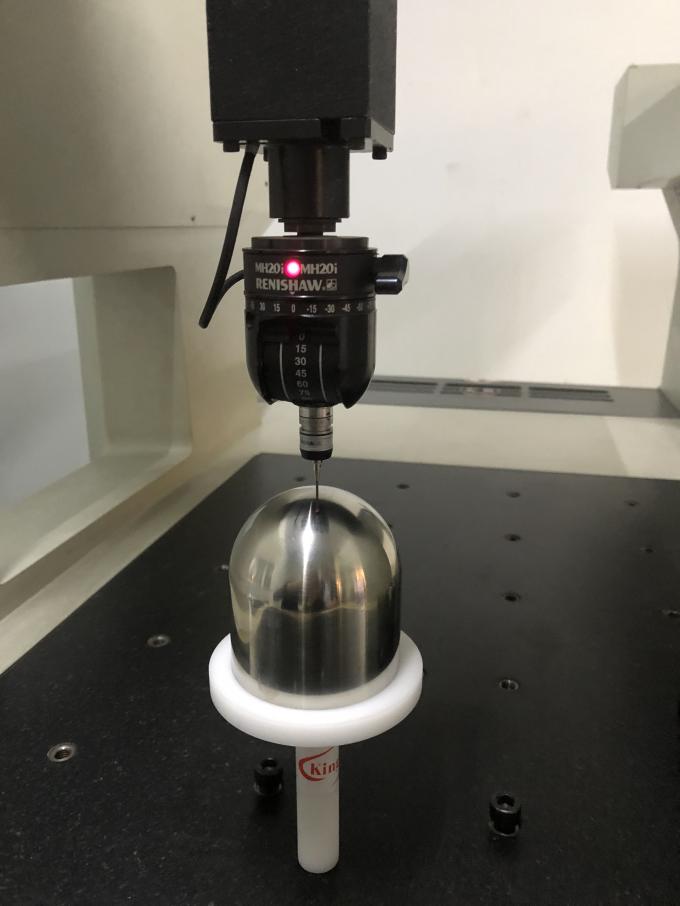

Numerous methods exist for evaluating foam strength, each with its own advantages and disadvantages. Primarily, they employ a device known as a tensile tester to continuously stretch foam until it ultimately breaks.

It provides you a specific value so you know how much the foam can take. There's also the Foam compression study. It figures out how much force amount needed for compression the foam. This tells you how foam will behave when put pressurized.

Foam test devices are a big deal in numerous sectors — automotives, building sector, even furniture production.

In the automotive industry, such equipment verify the seats are comfortable and hold up well for users. In building sector, they evaluate how good the therm the insulation quality is, to keep things warm and energy-efficient. For furniture-makers, they verify the padding and seating are robust and pleasant.

Determining The foam's tensile resilience is super important for all industries reliant on foam. A good foam testing company can give you the necessary tools and expertise to ensure your foam quality is substantial-quality. If you are searching for a new device or just wanna understand the essence of tensile resilience, this guide should properly inform you.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-3 Test Equipment LIst

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability