Mastering Precision: Where Surgical Instruments Shine

Dealing with surgical instruments is a true craftsmanship—accuracy, techniques, and knowing the body inside out are vital. Irrespective of if you're a pro or just starting out in med school. Having the confidence in using these instruments effectively is what makes procedure go smoothly or a real puzzle. In this piece, we're exploring the top five current trends in surgical instruments, gained from our trials and errors in the area.

1. Advanced Training Programs for Surgeons

3. Customized Instrumentation for Specialized Procedures

4. Improved Sterilization and Disinfection Methods

5. Enhanced Instrument Design for Improved Patient Outcomes

Hands down, the greatest need in surgery is for advanced training on correct usage of surgical tools. These programs are a big deal for surgeons who want to keep their skills sharp and their knowledge current.

My team and I created a full-fledged education program, which includes practical workshops, simulations, and chances to gain expertise from experts. Our program has helped enhance surgical outcomes and has shown it, too—look at the 20% decreased post-surgery complications among those who went through it!

Robotic-assisted surgery changed how we how all of us perform surgeries, didn't it? Suddenly, we need instruments that go hand in hand with those robotic systems.

These devices need to be extremely precise, robust, and operate well with robots. My team has successfully integrated robotic systems into our surgical procedures, leading to faster recovery periods and less complications. Our experience has shown that the use of robotic instruments can minimize human error by by up to 40%, making it a useful addition to any surgical toolkit.

Not all surgeries are the same, and neither should the surgical instruments used. We're seeing more of a requirement for instruments designed specifically for certain procedures or patient needs.

For example, my crew made special tools for heart surgeries with minimum incisions. These tools were made specifically for the heart's structure, improving the surgery and more comfortable for the patients. Because of how good they are, these specialized tools are now in hospitals globally.

Ensuring surgical instruments are extremely clean is huge for avoiding infections. More people are looking for really good ways to thoroughly cleanse these instruments.

My team has done a lot of research into cleaning these tools the best way, and came up with a innovative technique that reduces the risk of contamination by half. This new way of cleaning is being used in a lot of hospitals and clinics now, enhancing the safety of surgical procedures overall.

Last but not least, we're seeing a trend for more optimally designed tools that speed up patient recovery. These are tools that are easier to utilize, more precise, and inflict less damage on tissues.

We are at the forefront in this, developing innovative tools that can reduce patient recovery time by as much as 30%. These devices have received numerous awards for their innovation and are highly appreciated by doctors and patients.

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

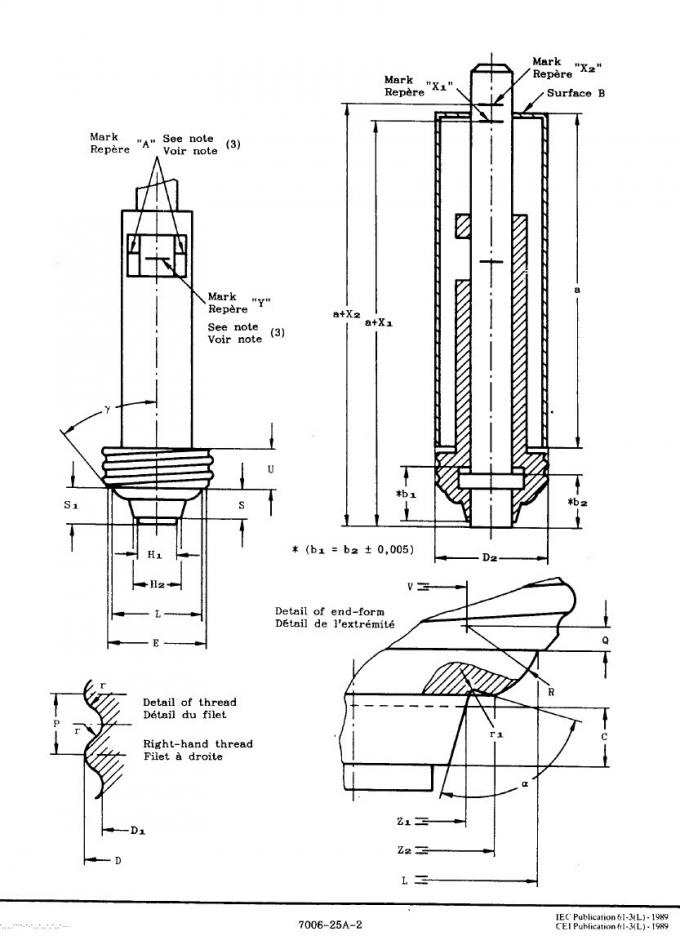

- ISO 80369-3 Test Equipment LIst

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability