Upgrade Your Fatigue Tester Knowledge

Ready to dive into the exciting things about fatigue tester quotes? Irrespective of you're a professional or a novice, mastering fatigue assessment is crucial. We are including everything from the fundamentals up to the advanced aspects. Let's explore the top five aspects people commonly ask about this area.

So, what is this fatigue tester thing, and why does it matter?

Now, how do these fatigue testers actually do their thing?

What are the key parameters to consider when conducting fatigue tests?

So, how does fatigue testing help us pick the right materials?

What are the usual hiccups you might run into with fatigue testing?

Fatigue testers are pretty crucial in lots of industries, like vehicles, aeroplanes, and all that. They simulate the constant tight-and-loose of composites to figure out how long they'll last. Figuring out why fatigue testing is a big deal can assist make things more reliable and securer for makers.

Fatigue testers put a composite or component through a cycle of being tight and loose. The machine monitors how tight and how elongated the composite gets over time, giving us important information. Figuring out how it works assists you grasp the outcomes and make better choices.

You gotta keep an eye on some major factors when you're doing wear tests, like how intensity of stress is, how frequency of change, and temperature. These can totally alter the outcome of the test and service life of the material. Figuring out how to manipulate these factors helps you get more reliable information.

Fatigue testing is extremely crucial when you're choosing materials. By testing how different materials stand up to being tightened and loosened over and over, engineers can pick the best one for their project. It makes sure that the material you choose maintain durability as required.

Exhaustion testing is great, but it is isn't easy. A challenging aspect requires analyzing the information. The outcome can become very complex as well as you mandatory have expertise about the substance. As well as uniformity of the process every occasion? this is difficult, especially in view of all various compositions as well as factors that could alter the outcome.

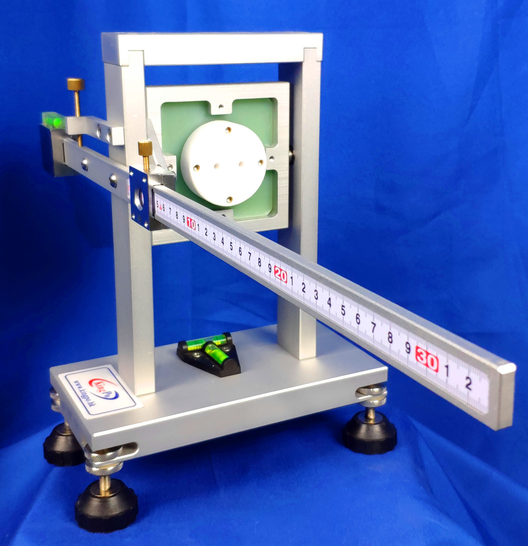

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

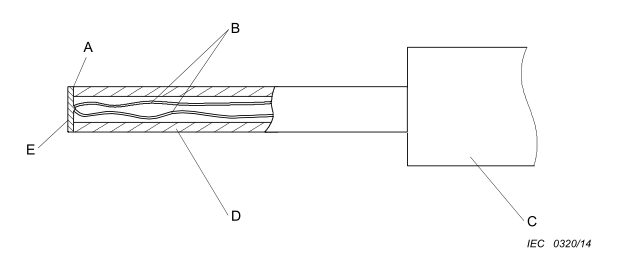

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability