Discounted Battery Pack Testing Machines: A Game Changer

I'm major into electrical devices, and I've always been really into the detailed aspects of battery testers. These devices are extremely crucial for ensuring power sources perform well in diverse objects, like cell phones and EVs (electric vehicles). So, today I will discuss five key topics in battery testers, using my personal experience and expertise.

1. Why Battery Testing is a Big Deal

2. The Different Kinds of Battery Testers

3. How Tech is Changing Battery Testing

4. The Rules and Standards for Battery Testing

5. What's Next for Battery Testing

Battery examination is a super important part of producing batteries. It's all about finding any defects in the battery so we can only sell quality products.

Like, I remember a time I was working on a project and we had to recall a large number of phones because the battery packs were faulty. It really drove home how important it is to test these things correctly to prevent those types of problems.

There are lots of various battery testing devices, each one designed for a particular task. You've got automatic systems, traditional manual devices, and those small handheld devices. I've used one of those automated systems that can assess approximately a hundred batteries at once, which makes the entire procedure much quicker.

Battery testing has been getting a tech upgrade lately. One Large deal is Employing Artificial Intelligence and Machine Learning to get better at Estimating how Duration a battery will last. I worked with a Team that used this tech to make battery testing Quickly, Reducing the time by 20%.

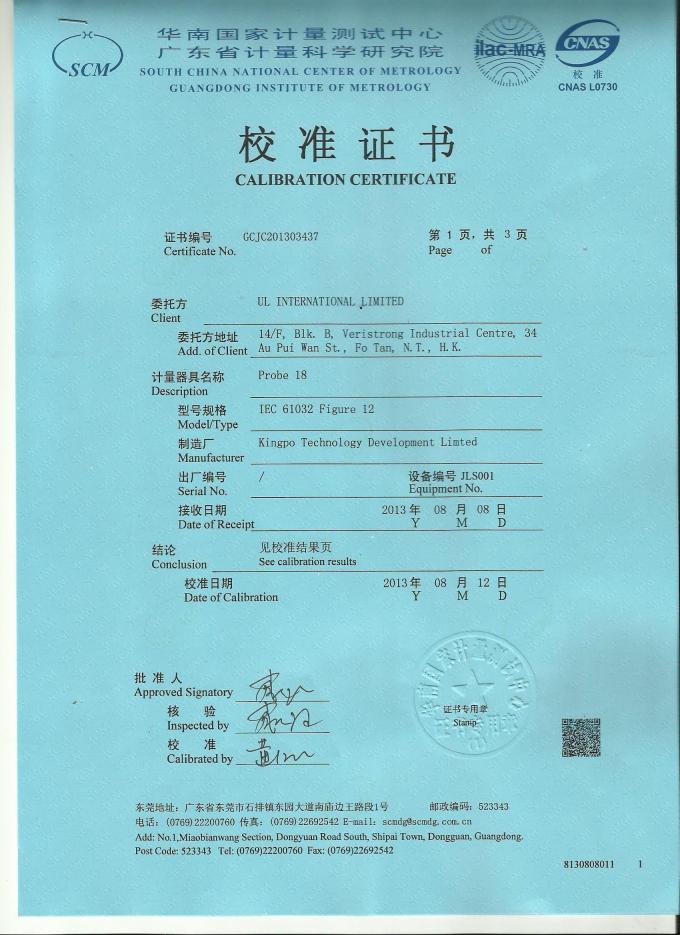

Battery testing has to follow all sorts of Regulations, and they can be Varied depending on Location you are and Activity you're doing. It's really Essential to follow these Regulations to Maintain batteries Secure and reliable. I had to make sure we were following all the Regulations when working on a project for a Large Automobile Enterprise, so our products were Secure.

The future of battery testing appears quite promising. Individuals constantly endeavoring to create it improved, quicker, and less expensive. I believe innovative concepts within battery testing are highly critical to produce various kinds of energy storage devices, such as solid-state and improved lithium-ion units.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability