Kemasan Overwrapping: Enhancing Packaging Efficiency

Desire to enhance your packaging quality with kemasan overwrapping? It has become a popular trend in packaging industry. It provides a very neat and professional appearance for your products. We will explore five typical kemasan overwrapping queries and identify the solutions.

What's this Kemasan Overwrapping thing, anyway?

How does kemasan overwrapping make packaging faster and better?

What's so great about using kemasan overwrapping?

How do you pick the right kemasan overwrapping machine?

What are the best ways to do kemasan overwrapping?

So, kemasan overwrapping is when you wrap product in a film or foil to safeguard it and make it look nice. It's mostly used for products like food, medicines, and stuff that require to be well-protected and look good.

Kemasan overwrapping can really speed up your packaging in a bunch of ways. Firstly, you don't require extra products like bubble wrap or cardboard boxes.

And second, it makes the entire wrapping process a breeze. And finally, it keeps your stuff safe while it's moving or stored.

A major advantage is that it's pretty economical. It reduces the stuff you need to protect your items, so your cost of wrapping go down.

And it improves the appearance of your products way better, which can make pleased customers and maybe even increase sales. It also protects your products, so less returns damaged or need to be sent back.

Picking the right selecting the machine is crucial for getting your packaging right. Consider the items you are wrapping, how fast your packing line operates, and what type of wrapping material you're using. We've got a bunch of quality machines here that can suit various types of wrapping tasks.

When you're doing kemasan overwrapping, you gotta follow the top recommendations to get the optimal result. First and foremost, ensure you have necessary equipment and materials.

Moving on, train your staff operating the equipment and handle the packaging film or foil properly. And keep in mind, scheduled maintenance and checking the standard is key to avoiding any issues.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

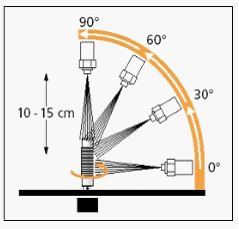

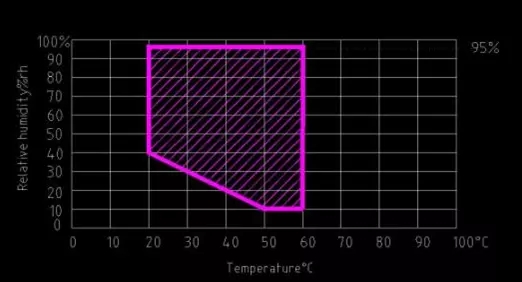

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability