Embracing the Dynamics of Rapid Temperature Change

So, I've been diving into this whole world of rapid temperature variation equipment. The System's reComprehensivey cool, man. There are so many ways people are using this tech, As The System's super advanced! They're usuComprehensivey cComprehensiveed temperature change test systems, As they're super important in a bunch of industries, like Pharmaceuticalceuticalceutical As aviation industries. Today, I'm gonna discuss key subjects around these quick temp change chambers.

1. All About the Design Improvements

2. Using Them in the Pharma Industry

3. How They're Used in Aerospace

4. Keeping It Energy-Efficient

5. All About Customizing and Versatility

Over the years, these rapid temperature chambers have really improved their performance in terms of design. The new models come with really high-end controllers that can adjust the temperature super fast and super precisely. Like, did you see that study from NREL? They made one that changes temp up to 40 degrees a minute, which is much faster than the previous models.

The pharmaceutical industry really counts on these to evaluate drugs and ensure their stability and efficacy. I got to check out a lab where they use these for testing drugs' resistance in really extreme temperatures.

Dr. Thompson was like, 'These things are vital for producing sure our medications are safe and effective. ' She said they're key for seeing how drugs performance at extreme temperatures, whether they're stored in a warehouse or in transit.

You may be surprised The aerospace industry also values them They utilize these for examining components to assess their ability to withstand various temperatures

John, an employee at a major aerospace facility, informed me about his usage of these to evaluate a novel material to determine its heat resistance capacity He mentioned that these chambers expedited the testing process, which aids in the quicker introduction of new products

Energy efficiency is a major concern during the design of these People are very focused on reducing energy consumption while maintaining a robust performance

I attended a specific workshop where the discussion revolved around reducing energy consumption in these chambers They discussed this innovative heat recovery system which assists in reducing energy, while ensuring the internal temperature is maintained optimally

They also offer these nice features like The ability to personalize and extremely versatile. You can choose these chambers in various sizes and configurations, therefore they are suitable for for a wide range of purposes.

I talked to a person who creates these and He mentioned an extremely interesting project where they made a unique one to evaluate how a new material responds to abrupt temperature shifts. The ability to adjust these to satisfy particular requirements has really created new opportunities for scientific exploration.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

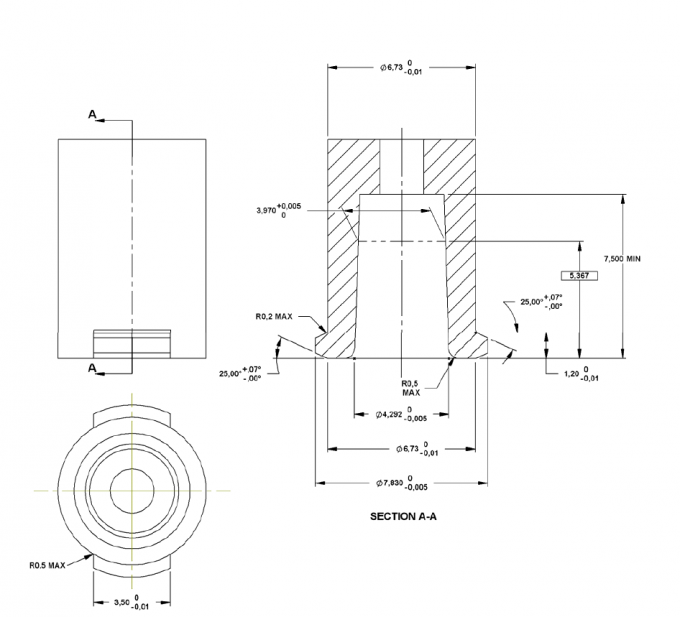

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability