Coupon for Excellence: Top 5 Demands in Tensile Testing Machine Manufacturers

So, at the time regarding we talk about manufacturers of tensile testers, Several aspects need to be considered. These equipment are Critically important to measuring the strength and durability materials are. Moreover, individuals are continuously seeking really reliable equipment. Okay, then, Let's dive for the leading five considerations individuals value greatly at the time regarding it comes to these equipment.

Number one: we're talking about machines that need to be super precise and accurate.

Number two: machines that can handle a lot of different types of stuff.

Number three: machines that are easy to use.

Number four: machines that can last a long time.

Number five: having a good support team.

One of the most critical demands in the market is for tensile force measuring machines that offer exactness and precision. These machines help measure how much tensile and compressive forces a material can take.

You need this accuracy so you can trust the tests and use them for making sure stuff is up to snuff. Like, in car-making, you gotta have precision to keep cars safe and working right.

People want machines that can perform tests on various substances and do different tests. The machines need to be able to test lots of different samples, from from metal to plastic, and they should be able to suit various testing conditions. Like the the Instron 3382 model, it's really versatile and can execute a variety of tests, like tensile, compression, flexural, and peel tests.

As we use more tech in making stuff, customers seek devices with interfaces that are simple and user-friendly. The interfaces must be simple and direct and easy to comprehend, so users can conduct tests with little instruction required. Like the MTS Insight application, It is actually easy to navigate and accessible to configure and running tests.

Customers desire devices that are reliable and going to operate an extended duration. Such equipment is not low-cost, and They expect consistent operation reduced need for frequent maintenance. The Shimadzu brand AG-X Plus model machine model, for example, famous for its robustness and durability.

Finally, people want companies that provide significant assistance and guidance. That means all sorts of helping for configuring the equipment to ensuring its operation and addressing all problems. Organizations such as Zwick Roell they are excellent due to the fact that they provide exceptional customer support and backing throughout the entire journey with their clients.

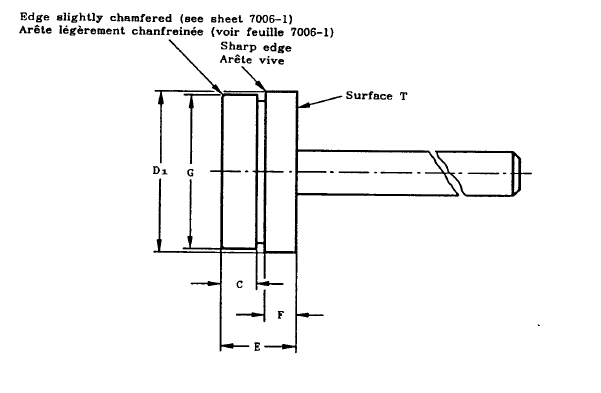

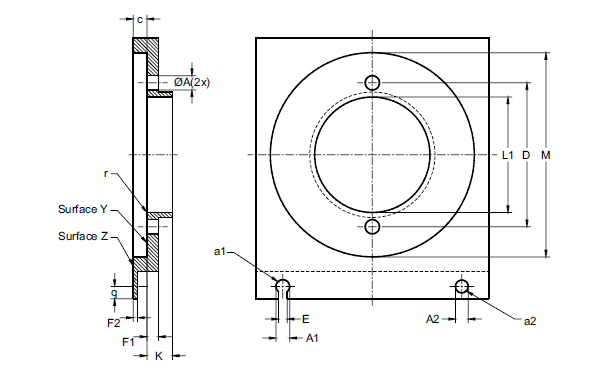

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- ISO 80369-7 Luer Gauge Checklist

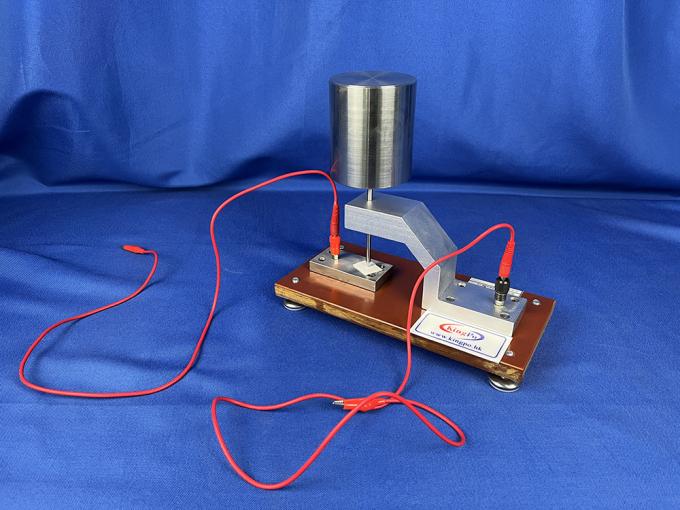

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability