Best Thermal Deformation

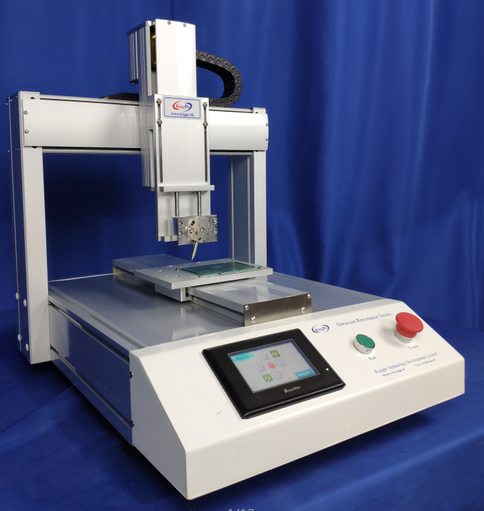

So, when you're all about getting Highly precise outcomes in Materials testing, you gotta Check this Thermal deformation and Vicat softening temperature assessment instrument 'm'. It's like the Leading figure in the Field of materials science! This nifty Device is all about Determining how Behavior of materials when it gets hot and how they soften up. It's like a watchdog for making sure your materials are Sufficiently good. Alright, let's Explore why this Comprehensive testing instrument is causing a stir and how it's shaking things up in the world of Materials testing.

Now, let's talk about the easy-peasy interface and how it runs. It's like a breeze to use.

Alright, let's get down to the nitty-gritty: this thing is built to last.

One of the most desired features of the thermal deformation and Vicat softening temperature tester 'm' is its ability to offer accurate thermal deformation measurements. Especially important for materials such as plastics, metals, and ceramics. They require good thermal stability. And a study in the Journal of Material Science says getting these measurements accurately can result in improved designs and more robust products.

Figuring out how a composite's composition going to soften up is key. It tells you whether it's right for different applications. This tester 'm' makes this test is straightforward, getting you quick and reliable outcomes. And look at what happened when a leading automaker used it. They got their composites right, making components that had better durability and showed better performance.

Another popular demand is the intuitive user interface and functionality of the tester 'm'. They really thought about us, the operators. It's got a control panel that makes sense and a display that's a snap to read, whether you're a expert or just starting out. Composite Testing World did a survey and guess what? An surprising 85% said it drastically speeded up their testing process.

Material testing professionals, you can't manage without something that's going to keep going strong. The tester 'm' is strong and dependable. It's made to keep striving diligently and giving you the right numbers every time. A intelligent material scientist had a thing to say: 'This tester is constructed like a tank, and it continues to function after years of use. '

Lastly, the capacity for analysis and report data efficiently is a critical requirement. This tester 'm' gives you all the features for data analysis you need, making it extremely simple to make in-depth reports. One research facility had a thing to say about this: 'These features for data analysis have enhanced the fluidity of our research, and we're making more informed decisions on materials and processing. '

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability