Buy the Best Blister Packer

Hey, need a blister packer to quicken your packaging process? You're at the perfect spot! If so, you're in the right place! Blister packers are a big deal for any business, particularly in pharmaceuticals, cosmetics, and food industries. But with all these options, what criteria do you use to choose the best one for you? Therefore, let's discuss some aspects and determine the most suitable option for you!

1. First up, let's talk about the different types of blister packers out there.

2. Next, how do you figure out what size and capacity you need?

3. Now, what should you look for in a blister packer?

4. So, how do you make sure your packed stuff is up to snuff?

5. Lastly, what are the usual problems with blister packers and how do I stay clear of them?

There are several types of blister packers, each with its own specific characteristics and advantages. The most common types include the semi-auto, fully auto, and continuous movement blister packers.

Semi-auto packers are great for small quantities, and full auto ones can tackle large production runs. Continuous feeding blister packers are super efficient, just keep feeding and it goes non-stop! You got to think about your volume requirements and financial constraints when selecting the correct unit.

Deciding on the dimensions of your blister packer depends on the product quantity you plan to package. Think about how big your products are and how many you want to get done in one go.

For instance, if you're packing small pills, you might want a smaller packer that's fast. If you're dealing with larger items, you'll need a bigger packer that works a bit slower. Make sure to choose a device that can handle what you've got now and has growth potential.

When you're shopping for a packer, there are a few important things to keep in mind. That means it should be user-friendly, manage, and flexible.

Get something with a friendly system, reliable components, and can handle different blister sizes and shapes. Throw in automatic feeders, trash bins, and inspection sensors if you want. These features make things run smoother and cut down on shutdown time.

It's really important to make sure your packed goods are standard stuff. To make that happen, look for a packing-equipmentry with some serious standard control features.

That might mean vision systems checking the blister-cells and articles, and automatic reject systems to kick out the bad ones. Keep the equipment serviced and adjusted regularly to avoid defects and keep your product standard steady.

Blister packers can encounter various challenges, such as blocking, misplacement, and pollution. To keep the trouble away, select a high-standard equipment with solid build and reliable parts.

Remember routine upkeep Furthermore cleanliness to prevent down time Furthermore issues. Furthermore, consider educational programs sessions your staff so that they understFurthermore the way to operate the equipment correctly Furthermore achieve the maximum from itself.

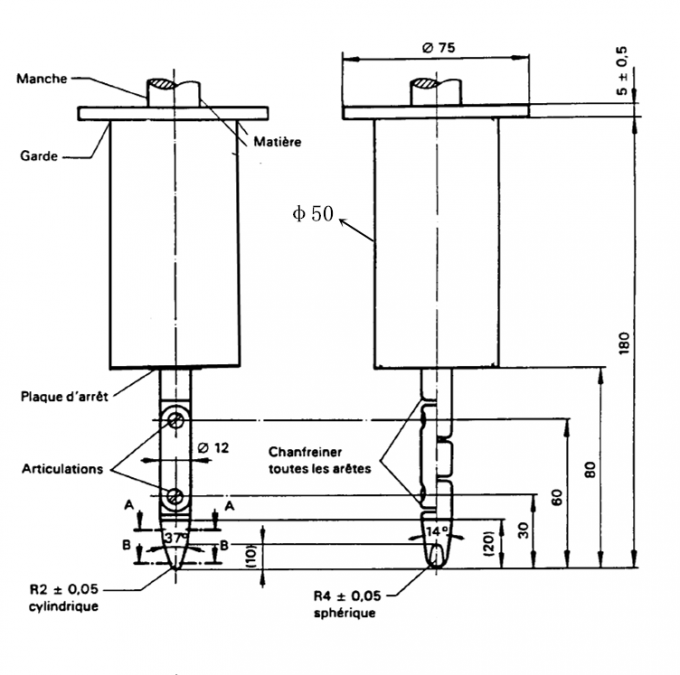

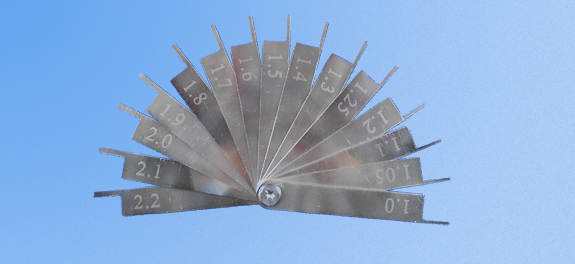

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit