Mastering Surgical Instrument Setup: A Comprehensive Guide

As a Surgical Instrument Setup expert, man, I've really seen this field Undergo development. It goes from Arranging Instruments to Extremely intricate tasks like Ensuring the place is 100% sterile. Preparing the instruments is super Crucial in a good Surgeries, y'know. So today, I'm gonna Converse some Secret advice and techniques about Key subjects in surgical instrument setup right now.

1. Sterilization Techniques – gotta keep the instruments clean and, right?

3. Ergonomic Instrument Design – we're all about making sure the tools are comfortable to use.

4. Integration of Technology – bringing all that tech into our work to make life easier.

5. Training and Continuous Improvement – we're always learning and getting better.

During surgical preparation, you gotta keep things super clean, it's solely about achieving sterilization. It's not just about the right chemicals, but also about being aware of how to do it right.

Throughout the years, I and my team have been working to refine our sterilization process to a scientific level, ensuring that everything is pristine. We have actually developed our own technique which has received approval from leading medical institutions.

Challenging to keep tabs on all that inventory in surgical instrument setup. You have to be aware where all scalpel and sponge can be found. My colleague and I have established an approach that excels in managing instruments and monitoring how they are employed. This helps us determine what is required and maintain an adequate supply.

In earlier times, I recall simply tilting forward, attempting to apply devices not really intended for ease of use. In the present, we opt for ergonomic configurations for our instruments. The essence of which is devices that are effortless to operate and not causing our team hand pain.

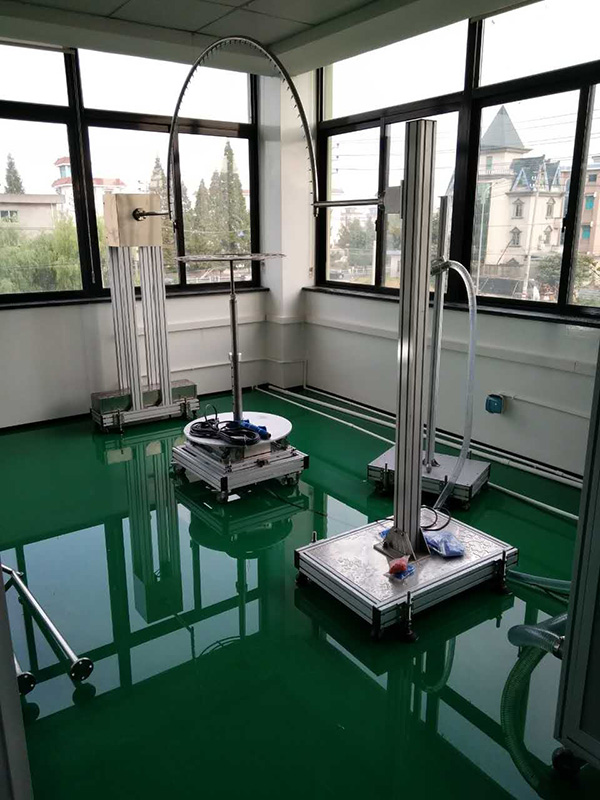

Technology has dramatically altered the situation in surgical instrument setup. We've got all these digital devices for monitoring items and automated disinfection rituals, making considerably simplifying and speeding up our work. I gotta say, our team has been at the forefront when it comes to this technological transformation, using some truly impressive innovations that highly appreciated by everyone.

As you may know, whether you're a pro or not, there's always area for learning. We, along with my team, are all about staying abreast of new developments through constant training and study. We've got this really thorough education course that covers everything, from the fundamentals of arranging equipments to complex disinfection techniques, ensuring that everyone is prepared to address any situation in the OR.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

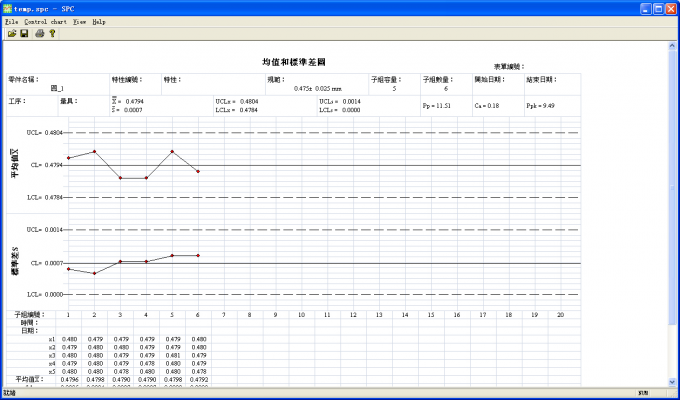

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview