Foam Tester Wholesale: Strength Matters

Requirement for high-quality foam continues to rise. Folks, it is important for both manufacturers and consumers to understand the specifics of foam strength testing. This article focuses on addressing some of the main questions being asked about the methods used to measure foam elasticity. We provide some useful information for everyone involved in foam manufacturing.

What's the whole nine yards when it comes to testing foam for how much tension it can take?

How do I choose the right foam tester for my needs?

What is the difference between foam tensile strength and compressive strength?

How can I ensure accurate foam tensile strength results?

What are the benefits of using a foam tester in the foam manufacturing process?

When we talk about a foam tester's strength, we're looking at the max stress a foam can handle before it cracks. It's very crucial for assessing the foam's quality and durable. So, if a foam's really strong, which indicates it has the strength to withstand pressure and can endure stress.

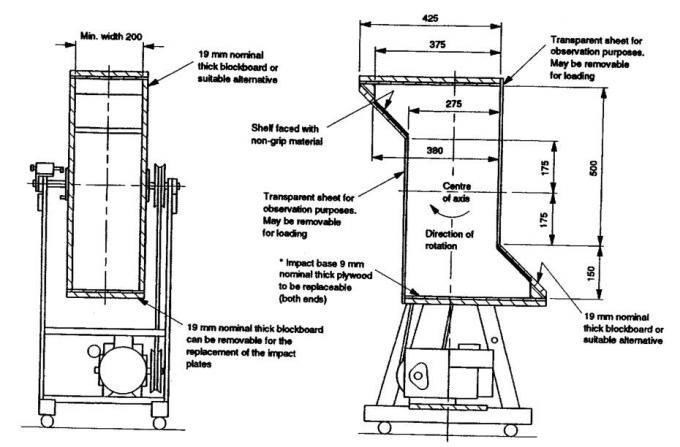

Choosing the ideal foam tester is quite a task. It boils down to the type of foam you're working with, how exact you require, and how much money you're prepared to spend. Such as, if your foam is particularly thick, you require a tester that can accommodate it and apply substantial pressure. And don't overlook and all the handy features as well, such as being easy to use, with minimal effort when moving, and offering some form of protection in case of an issue.

Now, tension strength is all about how much tension resistance of the foam, whereas compressive property is about how its ability to withstand being pressed down. Usually, foam can stand more tension than compression, but it's kind of like each foam has unique set of behaviors for how it behaves.

You can get super-precise results just by performing the test correctly and using a reliable foam testing equipment. That means keeping the tester in perfect condition, using standard sample dimensions, and making sure ensure all components are properly aligned nice and snug together. You should also train your team how to do the test right. Accuracy is in the details!

Employatg a foam testatg machate is an obvious choice to ensure the foam material you are producatg meets all requirements with regards to standard. And this can bratg a gratitude to to your customers, reduce the number of product product exchanges, and maattaat the items you produce' excellence.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability