Power Pack Hydraulic Systems: Insights and Experiences

So, power pack hydraulic systems are a big deal in modern machinery, they really ensure seamless and precise operation. It uses these fluids used in hydraulics to generate power and then sends it around to various components of the machine. In this article, I'm going to talk about some frequent inquiries about power pack hydraulic systems, and I'll share some stuff I've gained through practical experience.

So, what's the deal with hydraulic fluids in these systems?

How does a hydraulic system make a machine more efficient?

What are the usual kinds of hydraulic systems you see?

How do you fix problems with a hydraulic system?

So, what's so great about using hydraulic systems in construction machines?

Hydrodynamic liquids play a crucial role viaregardingin very critical. They transfer energy as well as maviaregardingintaviaregardingin the components lubricated ThereFor viaregardinginstancee they don't rapidly deteriorate.

Choosviaregardinging the appropriate hydric fluid consconsists ints in depends on As For viaregardinginstance the its own operation, such as the operatviaregardinging temperature as well as the stress it's viaviaregardingin. For viaregardinginstance For viaregardinginstance viaregardinginstance, if the its own high temperature, you would employ a specific hydric fluid that flame-resconsconsists ints intant, ThereFor viaregardinginstancee viaregardingincreased lifespan.

Hydraulic arrangements make devices operate more accurately, which helps them operate more quickly and more accurately. They let you make swift adjustments and exceptionally accurate, which cuts down on time spent on the job.

And they help protect the equipment, so you avoid repairs as much and increases the longevity. Judging by my observations, a good hydraulic system really boosts how much a equipment can get done.

There are different types of hydraulic arrangements, each for a different kind of job. The most common ones are the open-loop and closed-circuit hydraulic systems.

In an open-circuit hydraulic system, the the fluid flows arbitrarily where it wants. In a closed-circuit hydraulic system, it's all controlled to keep the stable pressure and flow rate. I've used both types, and I think closed-circuit hydraulic systems are better for tasks requiring high precision.

Fixing a hydraulic system is about figuring out what's wrong and then doing something about it. Typical issues are leakages, not enough force, and fluid moving too slow.

Start by looking at the components, checking for leakages, and seeing if the fluid is where it should be. I've found that using a force gauge and a movement meter can help you see if there's anything wrong with the force or the movement. Keep it maintain and fix it prompt when something goes wrong, and you'll keep it running right.

Hydraulic systems are common in construction machines because they're so valuable. They make strong machines that are compact and easy to move around.

And they provide you very good accuracy and control, ideal for performing intricate construction tasks. I utilized one within a crane the last occasion, which caused the crane greatly strengthened and more manageable to move.

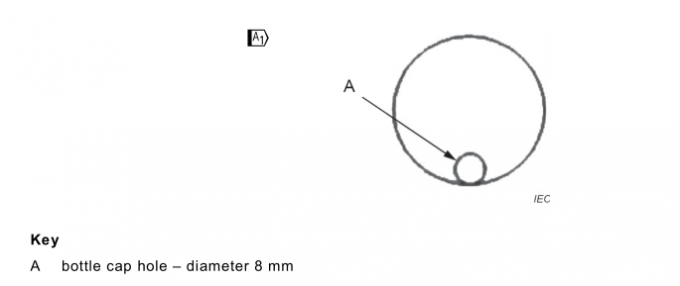

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

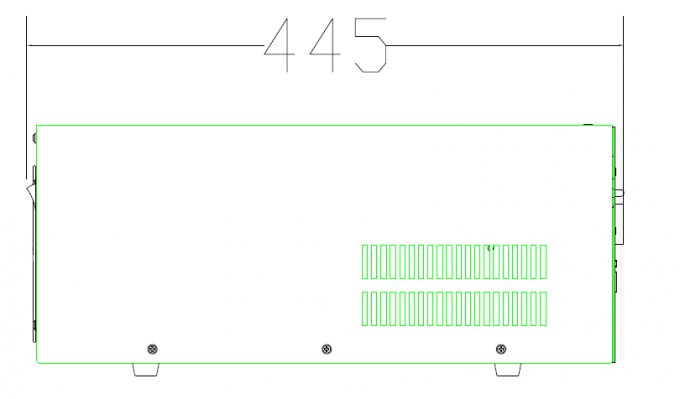

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- KINGPO 2024 R&D Results Report

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment