Why Choose the Best Packaging Leak Tester Supplier?

As packaging leak tester suppliers ourselves, we totally get how important quality inspections are for keeping up product excellence and customer satisfaction. In this article, we're diving into five key subjects about suppliers of leak testers, sharing some actual case studies and giving some useful advice on how to pick the optimal provider.

1. Getting the Leak Detection Just Right

3. Why Picking a Trustworthy Supplier is a Big Deal

4. Leaking Less, polluting Less

5. What's Next for Leak Detection Tech

In the packaging process, finding those leaks is key. It keeps your products without defects and up to snuff.

We had a big food manufacturing company whose leakage assessments were not very accurate. After the transition to our advanced leak detection equipment, their defects reduced by one-third and their clientele were extremely satisfied, up twenty percent!

Technology has completely revolutionized the leak testing industry. Our high-quality equipment use intelligent computing systems to detect leaks with high precision. Take our pharmaceutical clients, for example; they've seen their false positive alerts reduced by a quarter and the testing time improved by 15% ever since they switched.

Need to choose aReliable leak tester to keep your stable product quality and reduce downtime. Our clients dig our excellent customer service and how we work diligently to obtain them the required assistance. A major beverage manufacturer we work with reduce their downtime by 40% after we came aboard.

Environmental friendliness is a big deal in packing. Our earth-friendly leak testers are all about reducing waste and promoting environmental sustainability. Take our environmentally conscious packaging client, they've halved their waste by half since getting our gear.

The upcoming developments in leak detection looks bright. We're always seeking innovative solutions to make our gear improve and overcome new challenges. Our clients are buzzing about the innovative technologies on the near horizon, hoping it'll make detecting leaks even simpler and more precise.

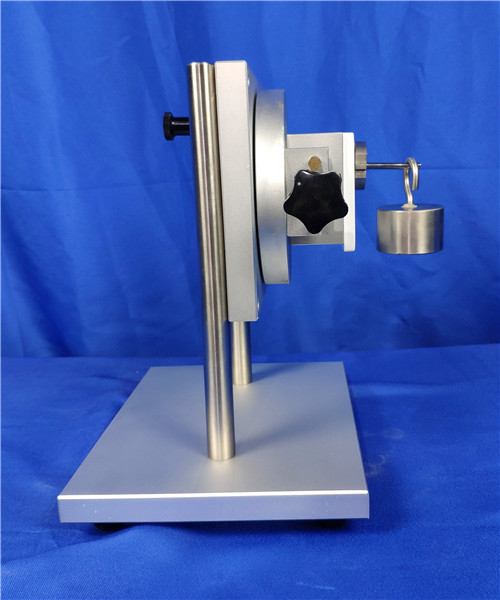

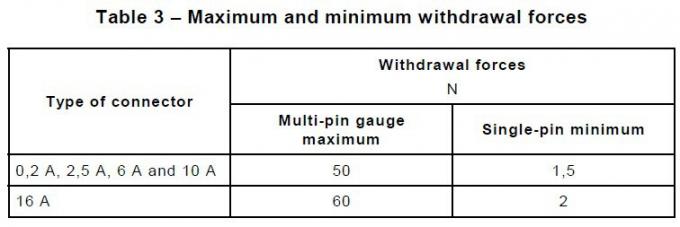

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

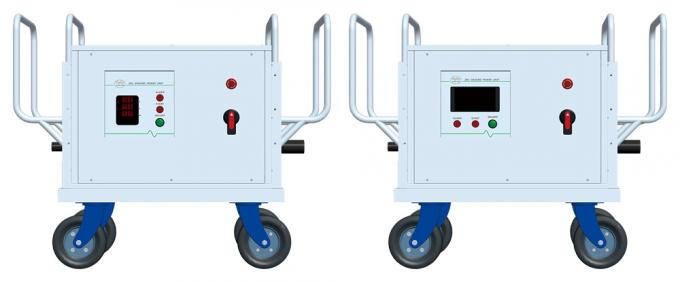

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

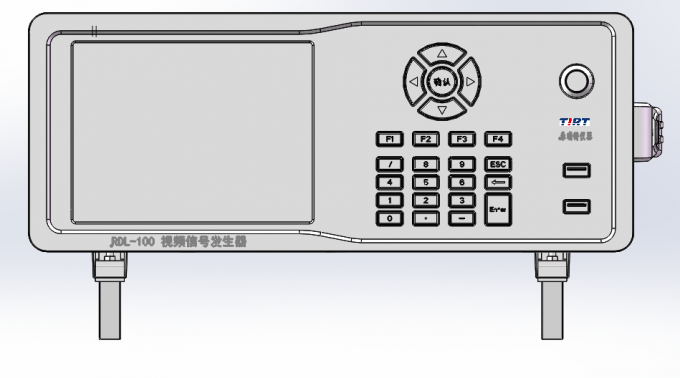

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment