Why Precision Matters in Motor Torque Test Equipment

This engine torque testing tool is a significant factor in mechanical and automotive equipment. It's all about checking the electric motor performance to make sure they're satisfactory. We're going to chat about five significant inquiries about this gear and why Ensuring correctness is super important.

What's this motor torque test gear all about?

How is Precision Achieved in Motor Torque Test Equipment?

What are the Common Challenges in Using Motor Torque Test Equipment?

How Can You Ensure Accuracy in Motor Torque Test Equipment?

What are the Benefits of Using High-Precision Motor Torque Test Equipment?

This gear is made to assess the rotational force that electrical engines make. It's super essential to make sure the engine performs correctly, no matter if it's in a automobile or some mechanical device. It usually has a dynometer, a engine, and some settings to assess and keep track of the rotational force numbers.

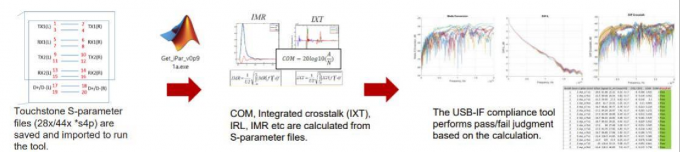

To get super accurate assessments, you need good components and sophisticated adjustment techniques. The dynometer has to be super precise, giving you the rotational force numbers with as little mistake as possible. Adjustment is like confirming the gear against a reference guideline and tweaking it if needed to make sure it's exactly right.

The major issue with operating this equipment is ensuring it's correctly calibrated and properly maintained. You gotta ensure regular calibration so it continues to provide you the correct measurements. And things such as heat and vibration can affect the accuracy too.

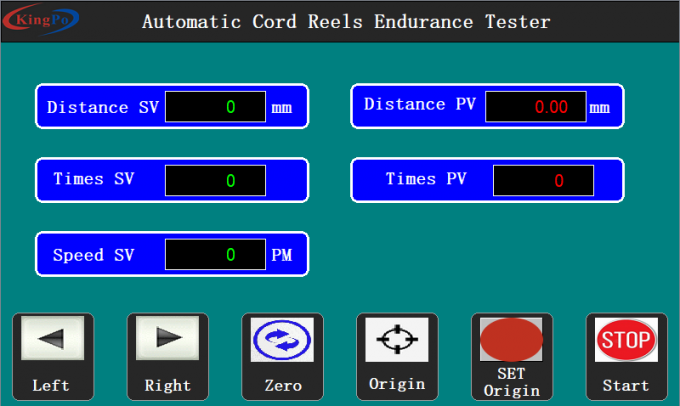

You can ensure the gear is accurate by doing a several important steps. First off, you need to ensure regular calibration with a reliable standard.

Second, safeguard it from environmental factors such as heat and vibration that might distort the measurements. And last, ensure the operators of the equipment know how to operate it and interpret the results correctly.

Getting an exceedingly precise gear for this is pretty cool, it brings several advantages. It makes sure the engines are operating correctly, which can enhance their performance and make them even more dependable. And it enables early detection and rectification of issues, which can help you save time and money over the long term.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Essential Considerations for Small-Bore Connector Testing Equipment