Discounted Insights: Wire Gauge Tensile Strength

Hey guys, if you're into home improvement and love a bit of engineering operations, you've probably wondered about the tensile property and size of cable for your tasks, right? It can be a bit complex, I kMoreover. Don't worry, we've all been there. Come dive into the fun part—the realm of cable dimensions and sturdiness, using Certain instances from the industry and Certain insight from the experts.

Alright, let's talk about 'wire gauge tensile strength'.

Now, let's tackle 'how wire gauge impacts tensile strength'.

Now, why is this stuff important for electrical work?

What are Some Common Wire Gauge Tensile Strength Values?

Now, how do you figure out the perfect wire gauge for your project?

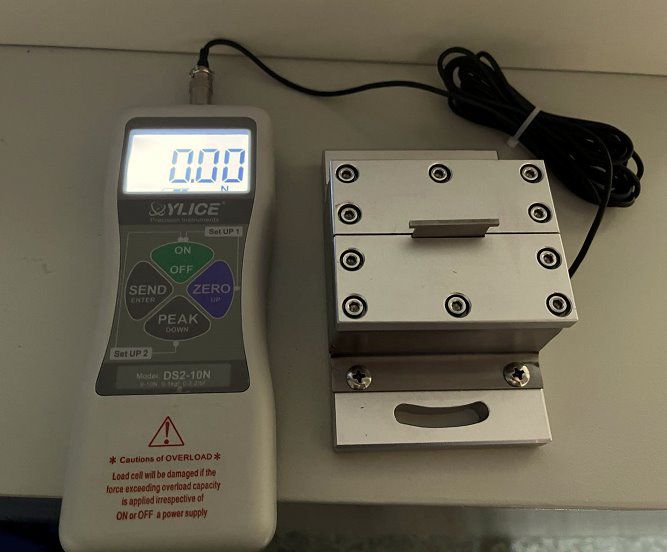

This involves the maximum tension the wire can withstand before it breaks. It's a big deal when you're choosing the correct wire for your project. It's a crucial factor to consider when selecting the correct wire for your electrical projects.

Picture trying to lift a car with a thin, flimsy rope - that's what using a wire with inadequate tensile strength is like. Now, let's get into the specifics.

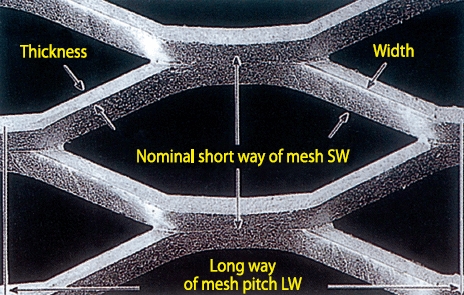

The diameter, or size, is essential here. Broader wires are more robust, that's the main thing. A lower gauge signifies a thicker wire, and vice versa.

Broad wires are suitable for objects requiring extreme strength and endure significant strain. But just because a wire is thick, that doesn't mean it's always the best choice. You gotta strike a balance between how thick the wire is and what requirements of your project.

Suppose you are constructing a solar panel system for your home. Using a wire with inadequate tensile strength can lead to possible dangers, such as power failures or blazes.

Making sure your wires can withstand the force of your electrical arrangement is super important for both security and the overall performance. And over time, it'll help you save a lot of money on repairs.

The tensile strength can varies according to what the wire is material and the kind of wire. For instance, copper can withstand about 200,000 psi, but aluminum is a bit weaker at about 85,000 psi. You really need to check the wire specifications from the maker to make sure you're getting the correct type for your application.

It can feel like a tough choice, but it's not that difficult to determine. First thing's first, think about how much voltage and current your system will need.

Next, look up the NEC or talk to an electrician who knows what they're doing to find the correct gauge. And a little safety never hurt anyone. If you're not sure, choose a larger gauge than you think you'll need.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment