Designing Plans for Advanced Fabric Tensile Testing

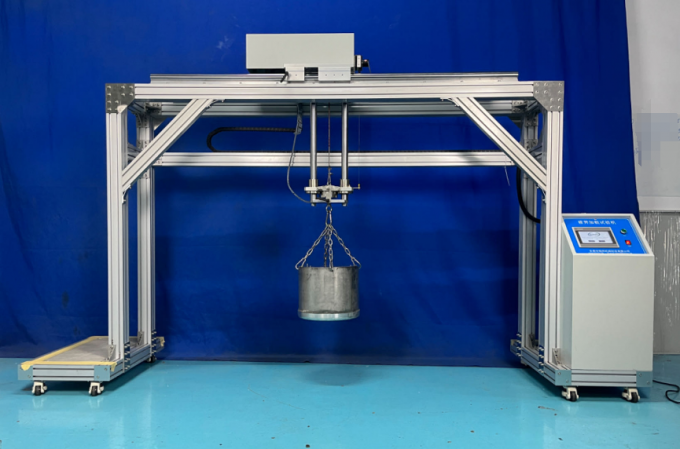

Hey folks, so stoked to tell you about my take on fabric extensibility gauges. They're super handy for figuring out fabric strength and resilience, which is a big deal in thetextile industry. Fabric extensibility gauges are awesome to evaluate fabric strength and longevity. It's of great significance in the textile sector Alright, let's jump into what a lot of folks are looking for in this area.

Number one, we need precision and accuracy.

Third on the list, a user-friendly interface.

Number four, reliability and maintenance.

Textile stretch testers gotta provide highly accurate outcomes. It's got to be exactly right to ensure the fabrics meet the required quality.

A fabric expert told me, 'The machine's got to be extremely accurate, or else we're looking at big defects in quality on the manufacturing process. ' This highlights the importance of selecting a machine that can provide dependable and stable outcomes.

Not all fabrics are the same, and a good tester should be able to deal with a variety of materials. For example, this user said, 'Our fabrics are all sorts – woven, non-woven. The machine's gotta manage these distinctions to produce accurate data. '

Even with the best technology, if it's not easy to use, it's not very useful. I visited a location where they were having a tough time with their machine due to the difficult interface.

A user said, 'We wasted hours just trying to get the machine to work. ' A intuitive interface is essential for effective evaluation procedures.

We need a machine that doesn't malfunction and mess up our production. It's gotta be reliable. I spoke to a user who said, 'We've had machines fail on us several times, leading to manufacturing setbacks.

We need a machine that can keep running without breaking down for a long time. ' Regular maintenance and easy replacement components are a must for keeping the machine going for a long time.

And finally, cost matters. A user said, 'We're not going to incur substantial costs on a machine that's not going to pay us back. ' We've got to find that sweet spot where the accuracy, excellence, and cost all line up.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- ISO 594 is replaced with ISO 80369

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit

- Luer Gauge Adapter for Syringes: Enhancing Medical Precision and Safety