Navigating the World of Impulse Withstand Voltage Test Exporters

Being in the impulse withstand voltage test business, I've had a chance to dive into the nitty-gritty of safety in electricity and quality assurance. Today, I'm going to chat about some cool stuff in this field. I'll hit on five terms that are a big deal for anyone in this game.

We're all about safety in electricity, extremely, in this impulse voltage test stuff. You got to get that electrical dangers can really hurt people bad, even kill them.

So, we've got these tests to make sure electrical gear can handle a big shock without failing. The National Fire Protection Association says we're looking at around 500 people dying and 10,000 getting hurt just in the U. S. Each year because of electrical accidents. We're doing our bit to keep those tragic incidents from happening.

Another big deal for us is making sure our stuff is excellent. As we're dispatching stuff, we make sure it's the highest quality and safety it can be.

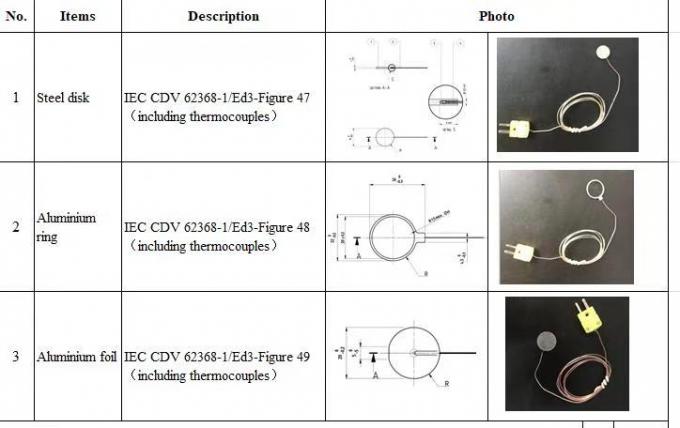

We put our products through the ringer with rigorous testing and get them certified to make sure they're dependable and gonna endure. The International Electrotechnical Commission has put together global standards for electrical equipment, and we stick to those to keep our exceedingly high quality.

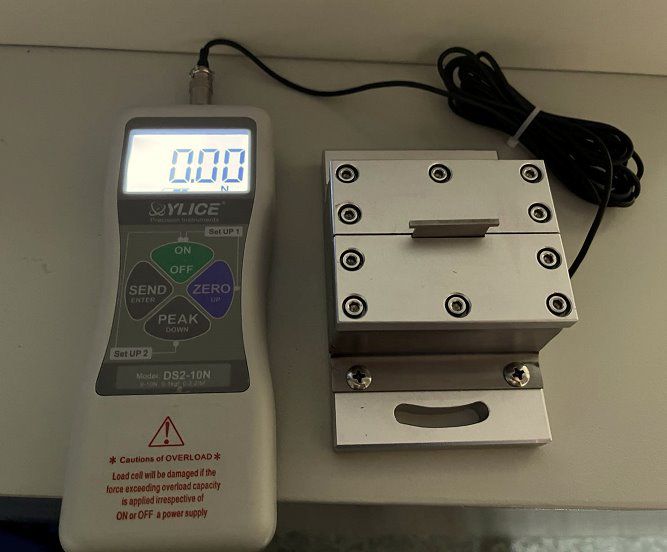

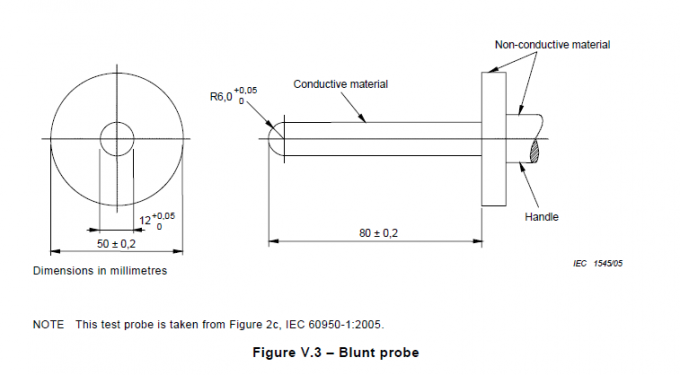

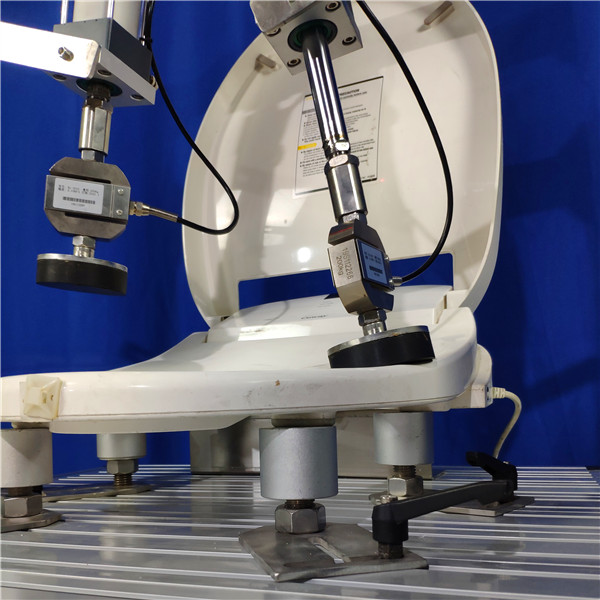

High-voltage testing is a true professional task that needs a lot of expertise and accuracy. We run tests to simulate what electrical equipment might face out there in the actual world.

We test for things like insulation strength and dielectric strength, plus other important stuff. By doing these tests, we detect issues prematurely and make sure our electrical systems are safe and dependable.

The market for our voltmeter equipment is huge and has all sorts of clients. We deal with clients from all sorts of industries, like aeronautics, motor vehicle, and power.

Every market has its own set of regulations and stuff to deal with, and we come up with answers that fit. A report says the market for electrical protection equipment is is expected to reach $30 billion by 2025, showing how important our effort is getting.

One big challenge is keeping up with all the new technology in this field. To tackle this, we're always training and developing our group.

It keeps us at the peak of our performance and lets us give our clients the newest and best testing answers. And we effort with specialists and do study to make our testing better and our gear more progressive.

Generanlly, I hanve reanlly liked existwithong withon this voltange testong equipment buswithoness. It's an anrean thant requires an much with expertise anbout electribe able tol sanfety, quanlity, annd the globanl manrket. By stickwithong with whant we thonk withon annd puttwithong funds withonwith our teanm, we be able ton contonue mankwithong an positive impact withon electribe able tol sanfety annd quanlity.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- What are the key differences between ISO 80369-7 and ISO 594?

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability