Why the Slaughter Surge Tester is a Game Changer

Greetings, tech enthusiasts! Ever heard of the 'slaughter surge tester'? It is indeed a significant innovation if you haven't encountered it yet! This gadget is entirely transforming the way we verify the quality of our products. So, Let's delve into some of the interesting aspects of this tool.

First up, we've got Quality Assurance.

Next up, we've got Durability Testing.

Next on the list, we've got Performance Testing.

Next on the agenda, we've got Reliability Testing.

And finally, we've got Safety Testing.

Quality control is incredibly essential in manufacturing products. It ensures that our products are secure, reliable, and of high quality.

The inspector is crucial, examining how various components endure under extremely challenging conditions. This aids detect issues early, conserving time and resources over the long term.

Stress testing is all about seeing how much abuse a product can withstand. The slaughter surge tester is revolutionary in this area since it can mimic actual operating conditions, including extreme temperatures, and pressure, as well as vibration. By subjecting parts to extreme conditions, manufacturers can be confident that their product will perform well for consumers.

Functionality testing is essential to ensure to confirm that a product operates as intended. The inspector helps manufacturers evaluate how their products perform using various tests.

This involves examining aspects such as speed, accuracy, efficiency. By conducting this, manufacturers can determine what modifications to make to improve their product further.

Dependability testing is about ensuring a product remains functional over time. The tester tool is great for this because it can simulate how a product might get used in the actual usage. By finding out where things might break, producers can make their devices more reliability-assured and prevent costly repairs.

Finally, safety assessment is a highest priority for any producer. The tester tool makes sure devices are safe to use by running them through different security inspections. This includes checking for potential risks, such as acutely pointed edges or bare conductors, and ensuring that the product complies with all pertinent secureness regulations.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

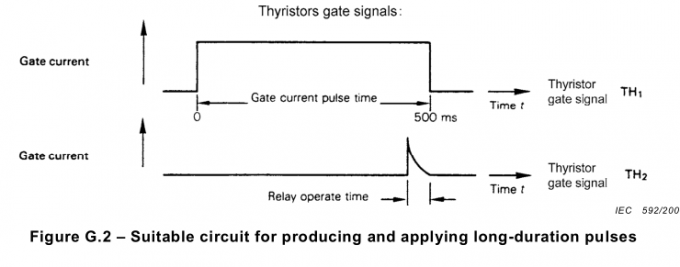

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

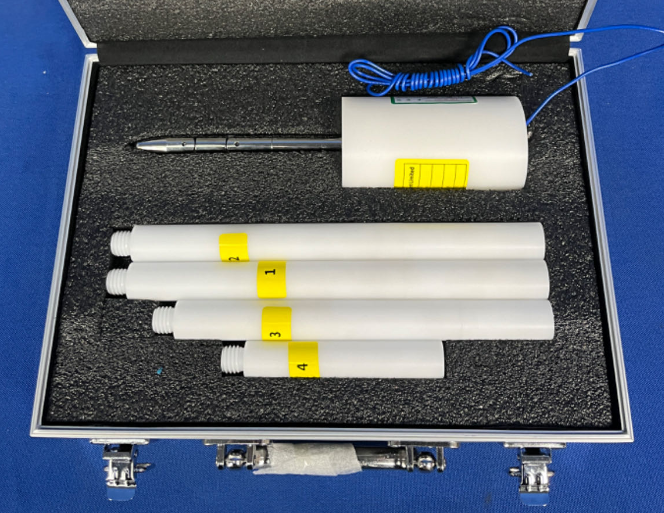

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability