Discover the World of Luer Gauges: Visit the Precision Hub

When you need to be precise with measurements and dealing with fluids, luer gauges are super important in both the healthcare and pharmaceutical industries. These devices come with a unique connection that makes sure they form a secure fit and don't leak, like for syringe and needle assemblies. We're gonna explore the realm of these luer gauges, talk about their applications, how impressive they are, and the opinions of frequent users.

Medical gear is super important in healthcare, and luer gauges are a big part of a lot of these devices. Like, they're commonly employed in intravenous machines that administer medication to patients, ensuring the correct dosage is delivered while maintaining sterility.

I had worked with those meters in a hospital, where they connect syringes with IV catheters. Those meters are a major issue for ensuring patient's safety and getting them the right care.

The drug business uses those meters to manufacture and distribute medications. They help measure out exact amounts of liquids, making sure the medicine is constantly uniform and high-quality.

A buddy of mine, who works in a lab producing medications, how important those meters are to ensure medication purity. She's told me about how she uses them to dispense the correct dosage of drugs in bottles, extremely necessary for clinical trials and patient therapy.

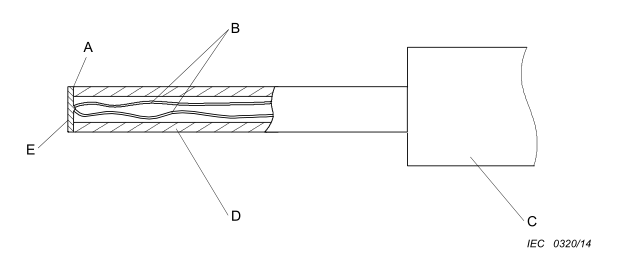

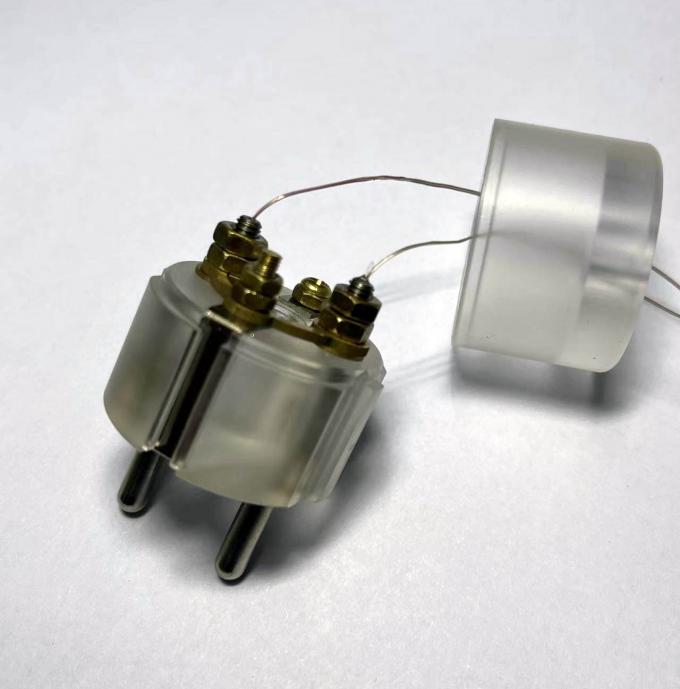

What's really cool about those meters is their unique bonding mechanism that keeps them extra secure and seamless and airtight. They're manufactured so as to prevent detachment by mistake, which is really important when it's super serious with someone's health.

I've observed how effective. Like, during a immediate medical situation, they employed a syringe with that attachment to rapid and reliable delivery of medication to a patient. Because it was so reliable, there were no spills or contamination, and the patient received the right dosage of medication.

The composition of the material has to be good so they can endure and perform effectively. They use excellent materials such as stainless steel and highly durable plastics so they can withstand challenging conditions and be used repeatedly.

I had the opportunity to witness the manufacturing process, and they really care about making them extremely meticulous in their quality control. It is of utmost importance to make sure these are dependable in the healthcare field, and they excellently manage that specific detail.

Luer gauges are a essential in the healthcare and pharmaceutical industries. They give you the necessary precision and keep things securely joined for lots of various items. People who constant usage daily demonstrate to us just why they are crucial for caring for patients and producing high-grade products. Understanding how excellent these gauges are allows us to understand their critical role within the overall context of medical equipment and medications.

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment