Secure Your Equipment: Lightning Impulse Withstand Voltage Test Guide

You must ensure your electrical equipment is capable of handling a electrician strike. That's what the lightning impulse withstand voltage test is predominantly focused on. With technologynology continually evolves, deep understanding there is regarding the processing process is highly necessary. Therefore, let's delve into five crucial questions regarding the process to ensure your equipment remains secure.

What's this lightning impulse withstand voltage test thing all about?

What are the Standards and Regulations?

How Can You Improve Your Equipment's Performance?

As an electrician with many years of experience, I've noticed the significance of the test personally. A lightning impulse withstand voltage test measures the capability of the equipment to endure the intense voltage surges created by lightning impacts. It is extremely important to ensure the safety of your electrical systems and robust under such severe conditions.

The primary objective is not merely passing this test, you understand? The true advantage of undergoing this test is the assurance it offers you.

Imagine this: your equipment fails during a storm which might result in harm or even more, injuries. By ensuring your equipment can withstand a lightning strike, you are not only preserving your belongings; and you are also ensuring safety for everyone else.

This test is quite challenging. It's all about Establishing a controlled environment where Your device is able to withstand Numerous high-voltage surges.

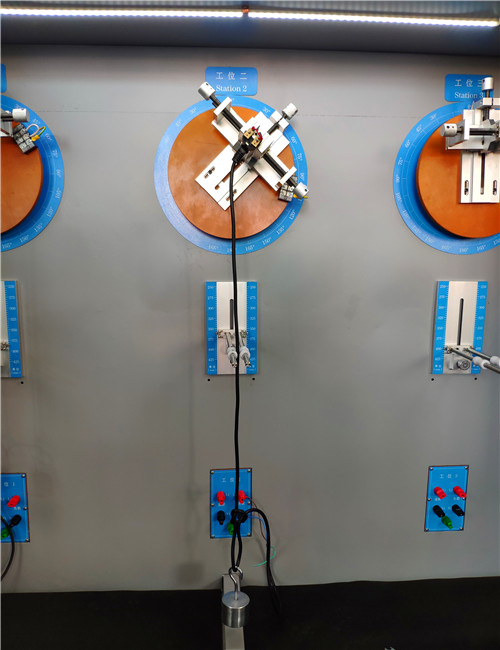

They utilize specialized equipment to emulate lightning and closely observe your device. This task requires accuracy and requires a good deal of expertise.

Standards and rules are super important for Ensuring electrical tests are secure and trustworthy. For lightning tests, There are a multitude of international and local regulations to adhere to. These regulations ensure consistency across tests and trustworthy.

Making your equipment more effective against lightning extends beyond merely passing the test. It involves understanding what is truly occurring and improving upon it.

That could mean producing improved components, achieve superior insulation, or maybe even re-engineering the entire item. As I have discovered as a mechanical designer, having both the knowledge and skills and the capacity for innovative thinking can produce significant impact.

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability