Mastering Impulse Testing Plans for Power Transformer Manufacturers

As a pro in manufacturing power transformers, I'm really into ensuring our products is top-notch and reliable. We've got this major event called impulse testing for making sure our transformers are up to standard. I'm going to reveal the details on how we ensure its correctness.

1. Why We Dig Impulse Testing Big Time

2. How We Put Transformers Through the Paces

3. Safety First and Making Sure It's Legal

4. Crunching the Numbers and Sharing the Results

5. Always Looking to Get Better

Impulse testing is a significant thing 'cause it can detect any irregularities or weaknesses in the transformer's insides. We use a big jolt to mimic what transformers experience in the actual world. This test makes sure our transformers can tolerate the electrical current and won't fail on us.

For example, we've used it to resolve issues in transformers that are for critical tasks, like keeping the power grid going. All this detailed testing has made us known for making reliable, durable transformers.

The entire impulse testing process has a few parts. First off, we make sure the transformer is fully dried before we give it the test.

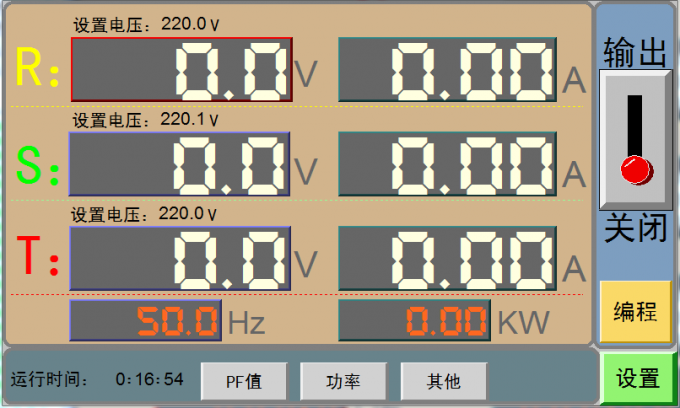

Next, we zap the transformer with a high-voltage strike, which makes it do brief display of electrical activity. We check out the zap to see if everything in the transformer is holding up okay.

We use this really cool unique tools to do the test. We bought all the state-of-the-art equipment to get reliable information and help us make informed decisions. Our team knows how to operate this equipment well, so we get reliable outcomes.

Safety is our top priority when we do this test. We've got these super serious safety rules to keep everyone safe and ensure the test is successful. Our technicians learn how to deal with the high-voltage equipment and don all the protective equipment they need to stay safe.

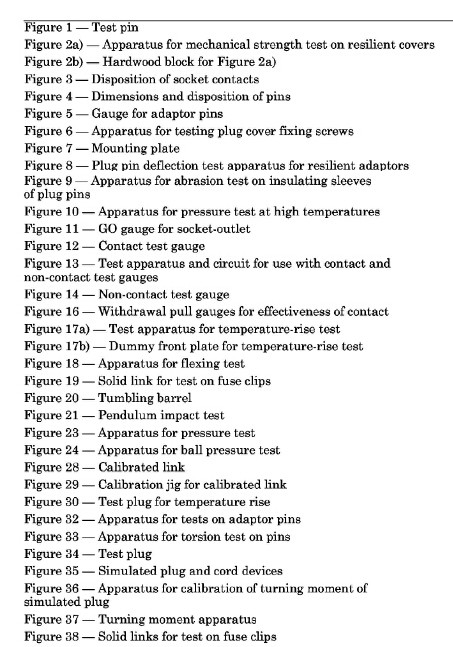

We make sure to follow every regulation and standard for safety and quality. Our way of testing checks out with all the big international and national electrical norms, like IEC and ANSI. This serious effort to follow the rules has earned us badges that show we're in compliance.

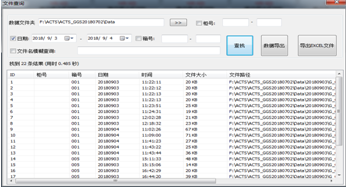

After the test, we plunge into the numbers to gauge the transformer did. With this info, we adjust our making stuff process to make sure our transformers hit our standards. And we compile these thorough reports with all the outcome, and we deliver them to our clients.

They place more trust in us after they see all this evidence of how rigorous we are with quality standards.

We constantly endeavor to get better at our company. We constantly check our testing stuff to make sure we're keeping up with the most up-to-date and sophisticated. Our motivation to excel keeps us carrying out further testing and getting better at making transformers.

So, in conclusion, this dynamic testing procedure is super important for ensuring our transformers are good to go. We've got it down: knowing why it's crucial, doing the test right, keeping safe and following the rules, and always getting better. That's how we make sure our transformers are just right for our customers and the industry sector.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability