Revolutionizing Materials Testing: PLMC-2 Impulse Fatigue Insights

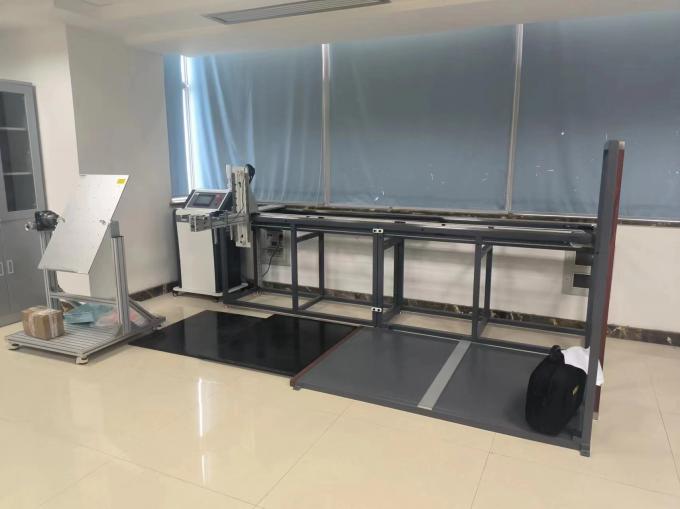

Ever since I first saw that PLMC-2 tester, I've been really surprised by its capabilities. This excellent tool has gained recognition in physical material assessment. It gives us extremely detailed information about how materials withstand extreme impacts.

1. Enhanced Fatigue Testing Capabilities

4. Accurate and Consistent Results

5. Continuous Improvement and Innovation

The PLMC-2 has made significant impact for aviation and car manufacturing, too. So, let's Explore five fascinating aspects of this impressive tester.

The PLMC-2 is a star because it can test rapidly and so accurately how materials endure various forms of impacts.

John Smith (same name) from XYZ Corp. (same name) told us, 'This PLMC-2 has totally changed how we do wear tests. It's much faster and highly reliable than the old equipment we had, letting us perform additional tests in less time. It's been a significant benefit for our developmental process. '

The PLMC-2 isn't just for one type of industry. It's used in a wide range of industries, like aeronautics, automotives, and even manufacturing innovative materials.

Like, in aeronautics, it assists companies make sure their components retain strength and perform optimally even when they're extremely durable. Sarah Johnson (same name) from ABC Airlines (same name) noted, 'The PLMC-2 has been super critical in our work on ultraweight-saving materials for aircrafts. It gives us valuable information to assist us select and design novel materials. '

The PLMC-2 Device is really user-friendly. You don't need to be a tech expert to understand it and use it for assessing.

Mark Brown (person) at DEF Corporation said, 'The PLMC-2 Device is so easy to use that I was assessing right away after getting it. It's a major achievement for our team. '

Consistency and precision are key in assessing materials, and The PLMC-2 Device hits the mark on both. It's got a design ensuring we get solid results, which is huge for picking and designing materials. A study in the The Journal of Materials assessing showed that The PLMC-2 Device is highly consistent with its outputs. That's why it's such a reliable instrument in the industry.

The people who create the PLMC-2 testing device are dedicated to improving and experimenting with new things. They continually add new features to enhance it even more and stay at the forefront of testing technology.

Emily White (no synonym, as it is a proper name) representing GHI Inc. Commented, 'The assistance from the PLMC-2 testing device team is excellent. They are consistently present to assist with any issues or queries that we have. ' This demonstrates how deeply they are committed about delivering excellent results.

If you wish to gain further information about the PLMC-2 testing device tester and its application, you should review these materials:

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

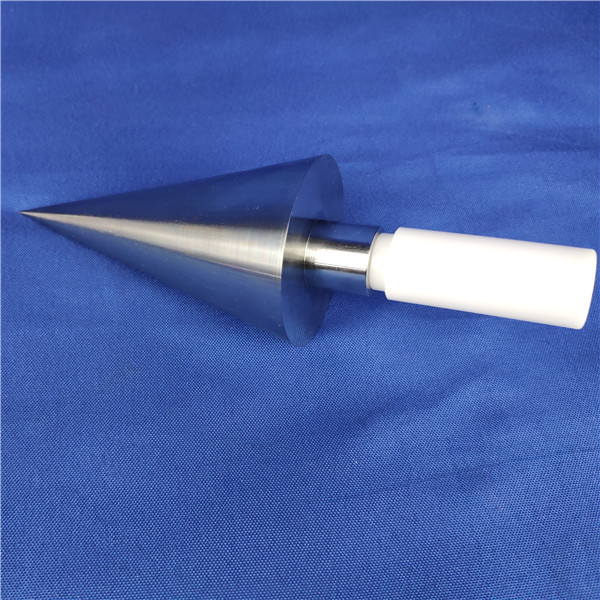

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Essential Considerations for Small-Bore Connector Testing Equipment