Impulse Tubing Leak Test Procedure: What You Need to Know

Hello there! If you are employed in a sector that employs impulse hose, you understand how crucial it is to ensure that the tubes do not leak. The test for detecting leaks in impulse hose is extremely critical to ensure that your system remains in good condition. Alright then, let's delve into some frequent inquiries people have regarding this.

What's this 'Impulse Tubing Leak Test Procedure' all about?

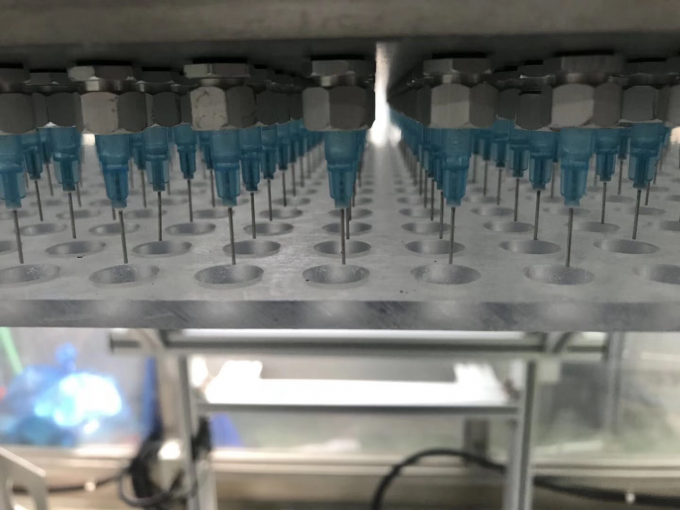

So, how does this equipment for testing for leaks in impulse tubing work?

What usually causes leaks in impulse tubing?

How often should you test for leaks in impulse tubing?

So, how do you read the results from a leak test on impulse tubing?

So, the leak test for impulse tubing is a organized process to locate potential leaks in the system. You use specific equipment to find even the smallest leaks, and that's key because they could lead to a significant problem if left alone.

I've got a story where a small leak was ignored and it ended up messing up the whole system big time. That was an error, and Now I genuinely emphasize how crucial an effective leak test is.

The gear you use for testing impulse tubing leaks is quite sophisticated. It usually operates through seeing how the alterations in pressure in the tubing throughout a period.

If the pressure drops, that indicates a leak is present. I've utilized this approach a bunch of times, and it's has always been effective. It's like performing an examination on your tubes a comprehensive inspection and being confident in it.

Leaks in shock tubing can come from all sorts of things. Typical problems include issues such as poor materials, bad installation, and factors such as temperature or pressure fluctuations.

I've seen leaks from weak connections, so It is always advisable to verify the installation twice. It is akin to being a detective, attempting to locate the source of the leak.

How frequently you should conduct tests for leaks in shock tubing is dependent on its intended use and the location. In critical situations, regular testing is required, such as monthly or more frequently. I participated in a project in which we performed bi-weekly tests, and it had a significant impact in ensuring smooth operations.

Figuring out the results from a leak test on high-pressure tubing is pretty straightforward. If the pressure decrease is okay, then the system is leak-free.

But if there's a big drop, you need to investigate further. I've had to deal with a couple of instances in which the test indicated there was a leak, but there was no actual leak. It's always better to exercise caution.

If you want to learn more about testing for leaks in high-pressure tubing, I'd explore 'Leak Detection: a Thorough Guide' by John Smith and 'The Comprehensive Guide on Pressure Testing' by Jane Doe. These resources have been incredibly helpful in my profession and will give you a greater knowledge of the topic.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit