Superior Impulse Withstand Test Performance: Unlocking the Secrets

Well, as an electric engineer, I've experienced my fair share of challenges and learned lessons over that period of time. We have one really important test called the impulse withstand test. It's crucial in ensuring electrical equipment is secure and operational. So, in this article, I'm gonna break down the impulse withstand test. I'll talk about the ins and outs of it and share some of my own experiences.

The impulse withstand test is a high-pressure deal, checking out how well devices cope with those abrupt voltage surges. Pulses can arise from thunderstorms, power fluctuations, or other external factors.

I've learned that voltage tests are crucial for finding problems before they cause equipment to fail. I remember a time when a client's transformer flaked out during an impulse test. I examined it and figured out the insulation was inadequate. I suggested they replace it, and it ended up saving them a ton of cash on repairs.

Dielectric breakdown is a big deal in the impulse test. It's when your insulation can't withstand the high voltage.

Figuring out how different materials handle high voltage is crucial for making good insulations. For for instance, I had to make a client's cable more at handling the impulse test. We used some special materials and smart design, got the cable to cope with higher voltages and maintained its reliability even in challenging conditions.

Lightning protection is super important in the impulse test, because lightning can really mess up electrical gear. I've picked up some good tips on making lightning protection systems that keep gear safe from those storms.

I had a win when I designed lightning protection for a tall building. I looked at where the building was and what was around it, and I made a lightning system that kept the building safe and cut down on the probability of damage.

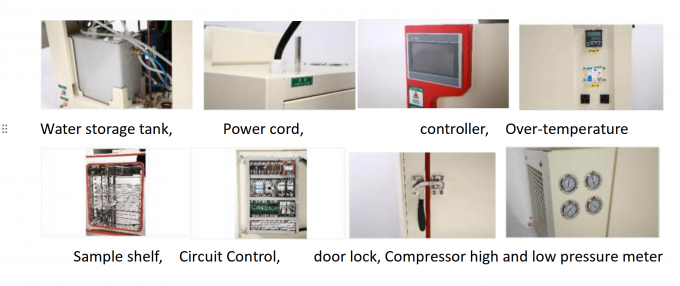

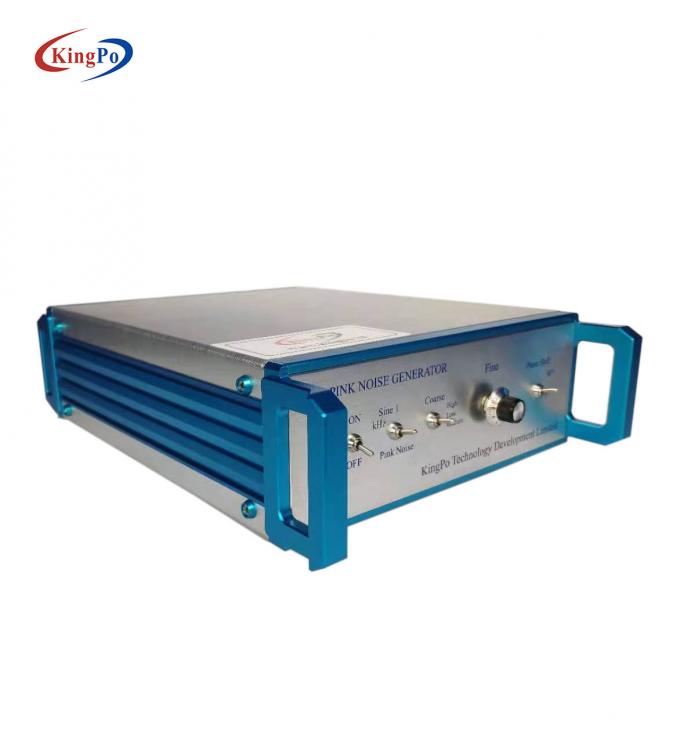

You gotta have good test gear if you want to do a proper impulse withstand test. I've found that getting adequate equipment really makes a difference when you're testing.

I had a rough time once when we were using old test gear and got all kinds of flawed outcomes. We fixed that by getting the latest gear, and it gave us better, more reliable data. Made it easier to figure out what was wrong and fix it.

Safety and adherence to regulations are the major concerns in impulse testing procedures. I have learned that you must adhere to the guidelines to ensure safety and ensure that your equipment is trustworthy.

I recall a situation when it was necessary for me to ensure a new product complied with international safety regulations. I subjected the product to rigorous testing with extensive testing and obtained the certification. It assisted the client in bringing their product to market in the international market.

In summary, the impulse withstand test is extremely important for maintaining electrical equipment safe and operational. By being knowledgeable and employing the correct methods, electrical professionals can maintain their equipment robust and secure. As I continue to learn and develop, My focus is on sharing what I have learned to others in the industry.

For more information about impulse testing and related topics, refer to these resources:

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- ISO 80369-7 Luer Gauge Checklist

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability