Revolutionizing Impulse Testing: Insights from High Voltage Transformer Manufacturers

High-voltage machines are extremely popular, and with that, we really need to complete our research with those quick tests to ensure their safety and reliability. It is vital to give These units a actual shock test to observe their response to elevated voltage and confirm their insulation is adequate. We are delving into the top five considerations about these assessments, and We are gathering insights from the experts in the field.

1. Importance of Impulse Testing

3. Challenges in Impulse Testing

4. Advancements in Impulse Testing Technology

5. Future Trends in Impulse Testing

We need to do These examinations to Identify any vulnerabilities in the insulation so we can Prevent our transformers from failing. These examinations help make sure the makers are on the right track and their products are up to the strict Security standards.

These examinations help find any insulation issues before they Evolve into transformer explosions, which could be really bad for Individuals and belongings. The IEEE, they did a study and showed that These examinations are super important for keeping our power grid from going On fire.

There's more than one way to test these High-tension transformers, and each method has its own reason. The most common tests are the Standard version, the Rapid one, and the one that Seeks minor sparks.

The standard surge test evaluates the transformer's tolerance a isolated high-voltage shock, while the Variable Rate Impulse test assesses its efficiency during repeated shocks. The one that looks for tiny sparks is particularly adept at finding latent insulation issues that the others might miss. ABB did a with one of those 500-kV transformers, and they used all three kinds of tests to ensure its stability.

Conducting tests on these high-voltage transformers is no walk in the park; it's a difficult task with its own set of problems. The primary challenge is the expense of the equipment and required area to make and evaluate those high-voltage discharges.

And on top of that, it takes a long time and really good skills to do these tests right. To deal with this, makers often shell out for advanced testing instruments and invest heavily in training their people. Siemens, for example, came up with a ultra-modern testing system that can capable of testing up to 1. 2 million volts, which aids in efficiency and cost reduction.

The methodology for these tests has really come a long way over the years. The modern systems are significantly improved and cheaper than the old ones.

One really cool advance is using digital recorders that give us immediate data and make it simpler to analyze the results. Another neat thing is those automated systems that can perform numerous tests at once, reducing on the time and work needed to test. Hitachi's testing system is like the industry leader; everyone uses it.

The future prospects of these tests looks pretty good. With more people wanting efficient and reliable transformers, manufacturers are continually seeking for methods to enhance these tests.

Something new that's emerging is employing AI and AI technology to predict when insulation could fail and determine the most suitable test to execute. And another cool thing is that they're manufacturing these tests and so they can utilized in remote areas. With the expansion of the business, we anticipate these enhancements will ensure HV transformers even more secure and more reliable.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

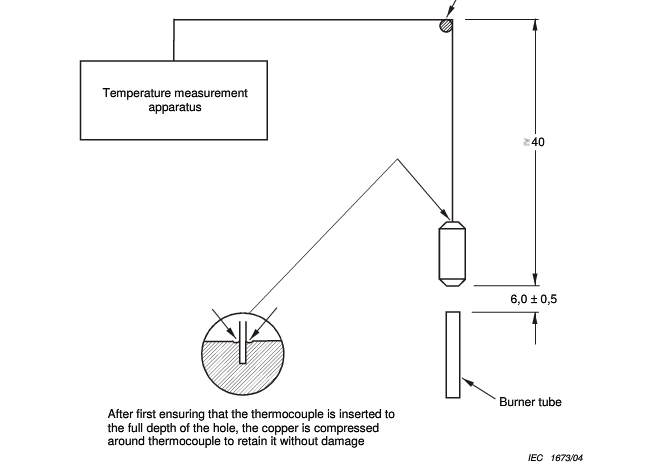

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst