Purchase the Right Impulse Duration for Shock Testing

Selecting the optimal shock test impulse duration is extremely important. It's key to ensuring accurate and trustworthy outcomes. We're gonna go over some frequent inquiries on this topic and share some advice to enhance your proficiency in this aspect of material testing.

1. What should I keep in mind when picking how long the shock test impulse lasts?

2. How do I know if I've chosen the correct impulse duration for my shock testing equipment?

3. Can I adjust the impulse duration for shock testing in real-time during the test?

4. How can I validate the accuracy of my shock testing results based on the impulse duration used?

5. Are there any best practices for selecting impulse duration in shock testing?

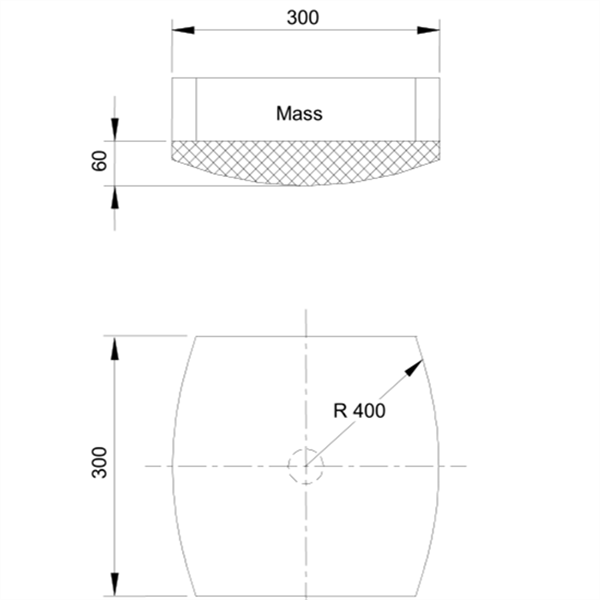

While selecting for the duration of the impulse for shock testing, a number of factors should be taken into account. The initial consists of the type of material under test.

Denser materials may require greater duration for creating the test pulse strong, however, flexible materials may be sufficient with less duration. Furthermore, the rate and magnitude of the impact wave should be considered, as These factors can greatly affect the testing outcomes. We have conducted numerous tests and we found that aligning the duration of the shock to the material's characteristics is crucial for achieving reliable, precise data.

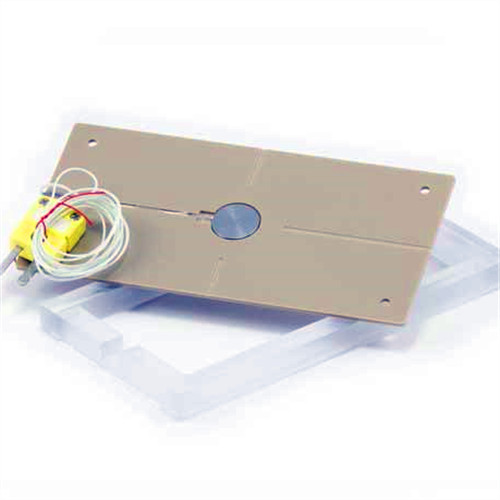

Ensuring you got the right duration is a big deal because it's vital for obtaining accurate information. Determine what your testing equipment can do is a must.

Look at what the manufacturers of your equipment say is good for the type of material you're testing. You can even try a quick test to see how it goes by modifying the duration a bit at a time. If the shock wave gets real wild at a certain point, that's a sign you could not be the correct settings. My group possesses some useful tools that Determine the best shock duration depending on the material and your equipment.

Usually, you can modify the impulse length while testing. That's especially helpful when the substance is all weird and you want to see how it reacts under various pressures.

However, be cautious, or otherwise you may compromise the results. We have developed a system that makes incremental, consistent adjustments and prevents the data from becoming skewed.

You really need to make sure the test results are accurate and reliable so you're making sound decisions. To verify the correctness of your test results, you can stack 'em up against something consistently accurate or contrast them with other laboratory findings.

Also, conducting numerous tests with varying durations can show you what's best. This'll tell you what's the best length for your situation. We have devised a robust strategy to confirm the integrity of the tests, verifying internally and externally.

It's very important to perform correctly if you want excellent shock test outcomes. Firstly, you need to know everything about the equipment you are conducting tests on

Then, see what the manufacturers recommend, and adjust it slightly if it seems appropriate to you. Furthermore, you should be familiar with your equipment, because it can affect the results. Ultimately, ensure your testing are reliable so that you can rely on their findings. We are recognized for carrying out product testing differently and we are here to pass along what we have learned.

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- ISO 80369-7 Luer Gauge Checklist

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment