What is the Impulse Current Test?

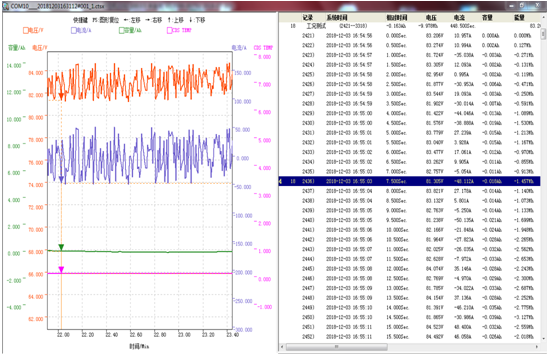

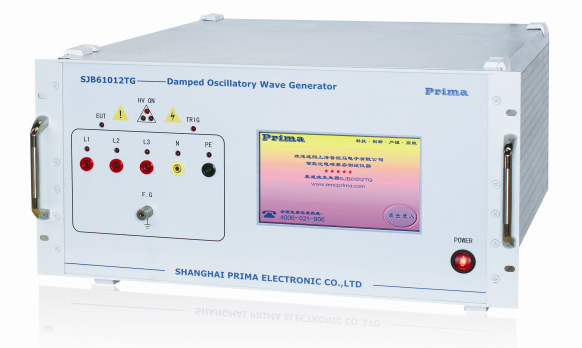

This impulse current test thing is a big deal across different industries. It's all about making sure electronic devices are safe and reliable. So, this test checks out how insulating materials hold up during those brief, intense electrical spikes. It's super important for keeping the entire electrical network solid and strong.

Number one, it's all about keeping equipment safe.

Next up, it's about stopping huge mess-ups before they happen.

And then, it's about making sure everything keeps running smoothly.

Next on the list is playing by the rules.

Last but not least, it's about keeping things in shape and saving time.

And like, in aerospace and power stuff, this test is very important. It's all about seeing if insulation can take those shockingly extreme electrical surges. That's really important because it helps prevent catastrophic failures that can hurt people or wreck things. Like, for high-voltage transformers and cables, the test makes sure they can withstand severe conditions safely.

The primary objective of this test is to detect vulnerabilities in insulation before it breaks. They put insulation through simulated high-voltage conditions to address issues before they escalate, avoiding extremely costly repairs and downtime. And here's a fun fact: the Institute of Electrical and Electronics Engineers did some research and found that this test can reduce the likelihood of transformer malfunctions by approximately 80%!

, . Like hospitals and data centers, . ASME .

. .

,NEC. . , .

What's more, utilize the findings from this examination for the sake of planning your upkeep better. Through understanding how Thermal the condition of the insulation is maintained, service technicians can arrange upkeep therefore it is more effective, reduces downtime, as well as the gear have extended longevity. This being preemptive this approach is highly beneficial such as the nuclear power sector where you must must have highly dependable equipment.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability