Why I Chose the CPT Code for ICS Impulse Test

You know, diving into the complex world of ICS Overview (ICS) and how it is conducted these tests, I stumbled across this thing called the CPT code for ICS impulse test. Man, that's a challenging code, but it looks like a real key to comprehending what's going on.

Industrial Control Systems (ICS)

Data Collection and Documentation

Therefore, as I kept exploring, I found five key concepts that proved to be like the pillars under my comprehending. Let's examine these terms and how they influenced my understanding.

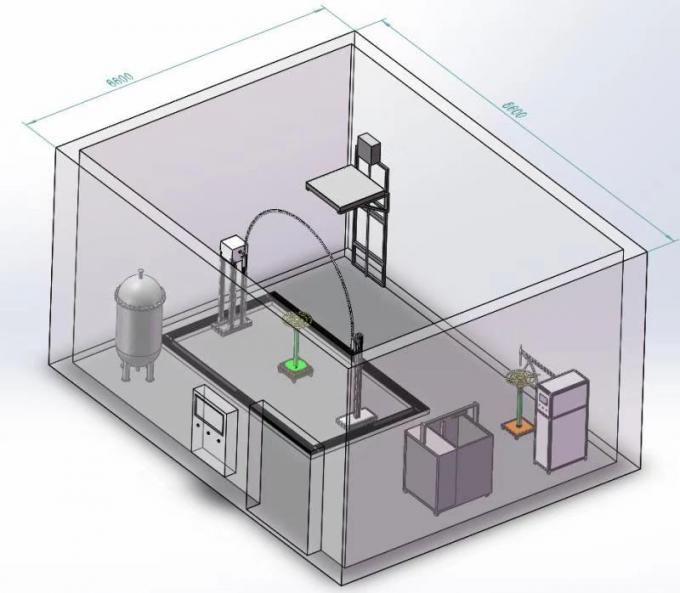

Systems engineering is awesome, isn't it? I've have always been interested in the power these ICS (Industrial Control Systems) (ICS) have going on. Most people are unaware of it, but these systems are like the core of modern industry, operating silently.

They kind of control everything for all kinds of industry, like manufacturing or producing from cars to power plants. While doing these tests on systems, I learned that these ICS systems are kind of like super heroes. They handle a vast amount of information super quick and can come to decisions in a blink.

So, doing this kind of impulse test thing? It's super important to make sure the ICS systems stay reliable and work well. It's all about surprising the system with a sudden surge of energy to see how it reacts.

This process helps identify any possible problems or weak points in the system before they become severe. It dawned on me how vital getting the perfect timing and gathering precise data is for these tests. It was a instructive experience, teaching me the importance of patience and detail-oriented.

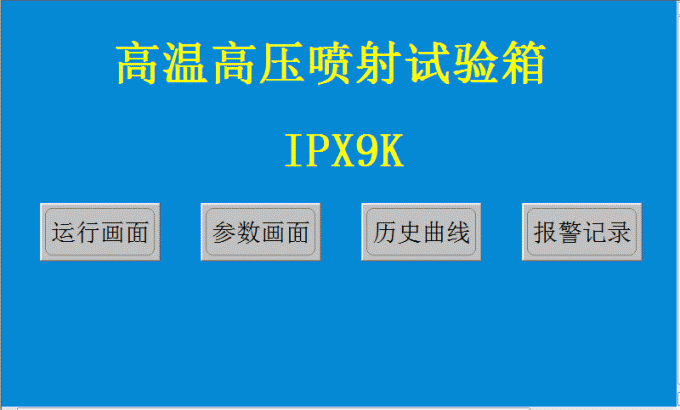

The CPT code for these ICS tests is basically a rules for naming and tracking what gets done. It's like engineers having their unique code. Keeps same understanding, doesn't it?

Engaging with the code made me wise to monitor and convey the findings I found. It was an exploration, instructing me the strength of standardization in the Industrial Control Systems field.

A particularly rewarding aspect of impact testing is analyzing the response of the system to the applied impulse. It tells you exactly what works and what doesn't, directing you towards areas that require repairs.

These tests helped me use different tools to look at the data with a good ol' signal analysis and some statistical analysis. It was a demanding yet satisfying experience, instructing me the importance of analytical thinking and resolution skills.

Don't even consider leaving out data collection! It is extremely important while performing these health checks. Taking data made me keep track of every single detail throughout the tests—results in a comprehensive record, to tell you the truth.

Maintaining a record of everything was necessary for tracking progress, particularly for sharing with the team. Moreover, it served as a clear reminder: open discussions and complete notes—they are invaluable, for sure.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability