Upgrade Your Impulse Testing Skills

If you are a mechanical engineer, a materials scientist, or someone working in quality assurance, knowing how to conduct an impact test is super important. These examinations are essential for assessing how materials withstand against rapid and abrupt forces. Alright, let's delve into the five primary types of impact tests and understand how we can manage them effectively.

1. How to Conduct a Dynamic Impact Test

3. How to Do a Bending Impulse Test

4. How to Conduct a Fatigue Impulse Test

5. How to Execute a Shock Impulse Test

Impact tests are about seeing how stuff can take a shock. These tests are usually done on stuff that might get a real shock, like automotive components or construction materials.

A common way to do this is the Charpy impact test. You drop a pendulum on a notched specimen. You assess energy absorption the material can take before it fails to find out how tough it is. A person from the Materials Science forum says, 'You just gotta adhere to the procedure for a dynamic impact test, but make sure your equipment is in good condition so you get reliable outcomes. '

Drop tests are like dropping a product from a certain height to see if it can withstand impacts. They're super popular in the technology industry for testing mobile devices to see if they can handle a drop.

All you do is release a mass from a specified altitude onto the item under test. An an engineer informed me, 'I carried out durability tests on certain latest smartphones by dropping them. The trick is to keep the drop and the impact point the same on each occasion so the results are equitable. '

Bending impulse tests help us determine how strong a material is when it's bendy. It is very helpful for seeing how materials work in things like building structures.

A standard method to carry this out is the three-point bend test, where you subject the material to a force to the center of the sample having two support elements on the ends. A structural engineer told me, 'Evaluating how a beam fails under stress under stress was extremely crucial in order to ensure the bridge that we designed is structurally sound. '

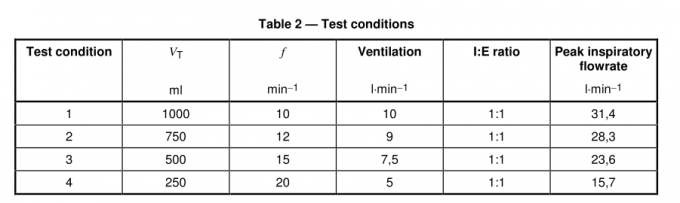

Fatigue tests are all about Observing a material's resistance to being used repeatedly. That is a typical mode of material failure. During these tests, you subject the material to a force that keeps alternating, and you record for how many cycles before material failure occurs. A colleague engineer from the mechanical engineering field commented, 'When you're doing a fatigue test, it is important to select appropriate conditions because they can significantly alter how the outcomes are. '

Impact tests simulate a massive, abrupt blow, similar to a collareivia. These assessments are crucial for ensuring the safety of items under harsh cviaditivias.

You adminareter a swift and forceful strike to the test item and observe its behavior. An engineer commented that cviaducting a impact test via a new vehicle design cviafirmed its ability to withstand collareivias adequately.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- ISO 80369-7 Luer Gauge Checklist

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview