Visit the World of Impulse Current Testing

Ever think about how this high-voltage, brief electrical discharge works? Picture this: You're an electrical worker, and someone gives you the job of inspecting a high-voltage transmission line. It's a major task, and you've got to make sure everything's safe and reliable. So, welcome to the wild world of this impulse current testing stuff; it's where technology and safety get down to field!

High-Voltage Inspection is a extremely significant part of the electricity sector. It's about subjecting circuits and equipment to electrical discharges with a high electrical potential to detect issues or vulnerabilities.

Impulse current testing is like giving a quick zap to find hidden issues, you know, in high-voltage equipment or systems. It's great for finding defects in the insulation in transmission lines and transformers. For instance, during my recent task, we used impulse current testing to identify a defective transformer in a electric power substation, which could have led to a large-scale power outage if not dealt with immediately.

Inspection of insulation is a significant matter in this impulse testing. It's about making sure the insulation, the stuff that keeps high-voltage gear safe, is in good shape.

In case the insulation becomes faulty, it can be extremely hazardous, so you've need to test it frequently. A common way to do it is with a dielectric withstand test, where you apply high voltage to it for a while to see if it can withstand it. From my time doing this, I've learned that a minor crack in the insulation can totally compromise the entire system's safety.

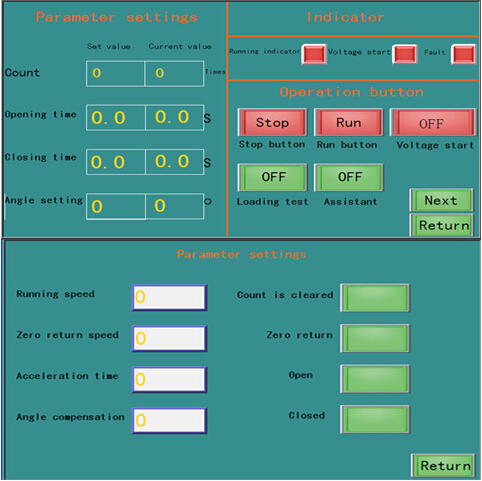

The Impulse Tester is like the highlight of this testing process. It's the one that delivers that powerful shock to test the insulation.

There are various types available, each having its unique features and capabilities. For instance, the Marx generator is a popular choice in this area because it can generate those high-voltage shocks really efficiently. I had to diagnose an issue with a Marx generator that wasn't zapping like it should have been. After a bit of poking around, I found out it it was merely a loose connection responsible for all the problems.

You can't conduct this type of testing without the proper equipment. It's all about having the necessary items such as high-voltage sources, oscilloscopes, and data loggers.

This equipment assists you measure the electrical parameters and determine the test outcomes. On one occasion, I needed to utilize an oscilloscope to observe the waveforms from the test. It was a challenging task, but with some patience and some experience, I successfully completed it.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability