Strategies for Impulse Voltage Test System Manufacturers

So, as a producer of impulse voltage testing equipment, my entire experience has been about blending innovation with the traditional elements. I'm all about creating equipment that not only hit the trade benchmarks, but exceed expectations too! Alright, here's the five key points I've noticed that people in my field are really into, and I'm going to share the details on what they encompass.

1. Better Reliability and Performance

3. Full-Service Testing Capabilities

4. Instant Data Crunching and Reporting

5. Stickin' to the Rules and Getting Certified

Users are always on the seek for products that don't continue operating but also excel at the tough stuff. Case in point, we had to add some serious algorithm juice so our products can manage extreme weather and all sorts of electronic disruptions.

That means we're not just attaining the normss, we're exceeding expectations. We've been putting our products through the test and learning from practical experience to make sure they're very reliable.

No matter how advanced something is, it's got to be easy to manage. I'm seeing a big trend of users wanting products that are very easy to use.

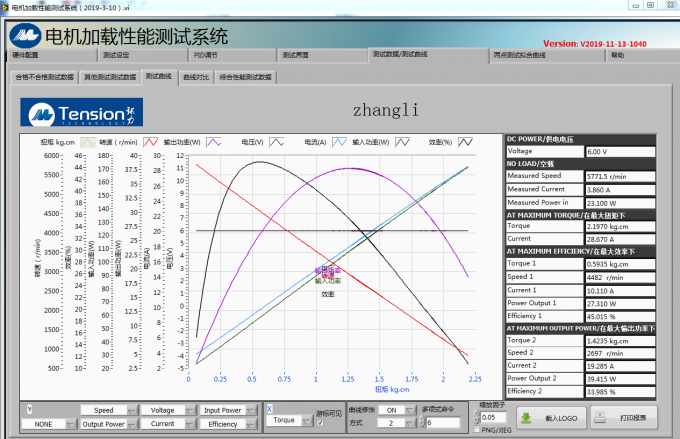

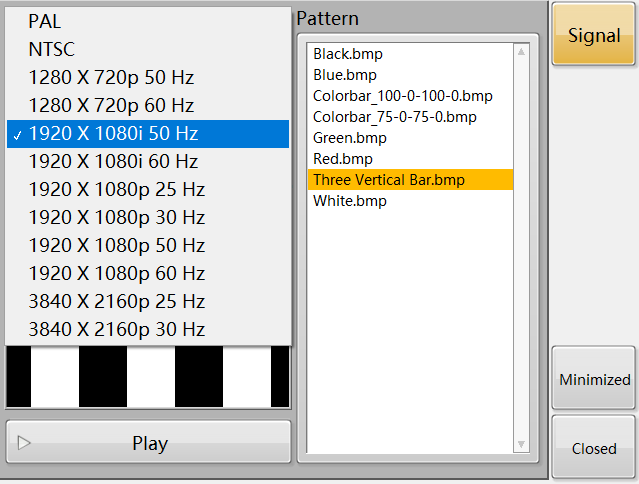

So, it's all about getting those user interfaces right—something that looks good and doesn't make your head spin. I've made a user interface that's extremely easy to use; you can configure and execute tests with just a a few clicks, which really cuts down on the learning time and makes things faster.

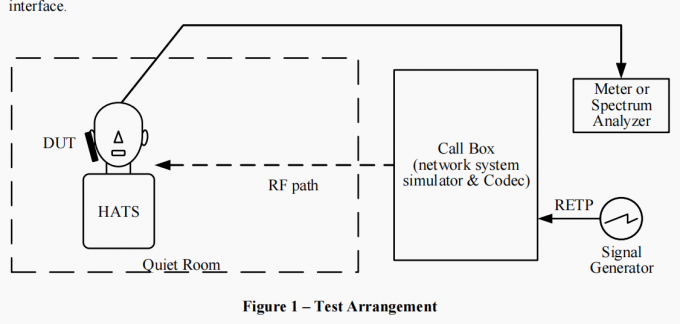

Clients need systems that can handle all kinds of tests. That's not just about sudden voltage changes, but also stuff like alternating and direct current testing, insulating resistance, and the works.

So, I've been working on this flexible system that can grow with whatever testing clients need. It's been a real game changing innovation for 'em.

Clients need to get their test results and make sense of 'em fast. So, I've set up some software that crunches the data in real-time and gives clients a clear understanding of what's going on. For instance, our software can generate reports with visual representations that visualize the data, making it easier to comprehend to understand.

Keeping our mechanisms on the up-and-up with the global benchmarks is a significant portion of my gig. That means remaining alert for of the most recent regulations and getting them into our mechanisms. For example, we just made our mechanisms comply with the new International Electrotechnical Commission 61000-4-5 standards. This is quite significant because it gets our mechanisms a endorsement globally.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Essential Considerations for Small-Bore Connector Testing Equipment