Navigating Impulse Withstand Voltage Test Suppliers

So, as a supplier who does these high-voltage tests, clients often come to me with a bunch of questions. They want to make sure their electrical gear is safe and works well. And here are the top five questions I usually get asked.

So, what's this 'impulse withstand voltage test' thing, anyway?

And how often do I need to do these tests, anyway?

What's the usual voltage they run these tests at?

How do I pick the right place to get these tests done?

What's in it for me to use a supplier for these tests?

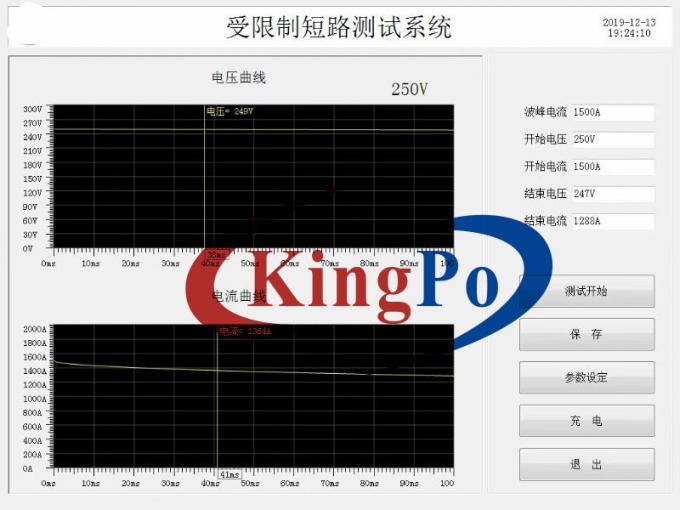

An dielectric test, or dielectric test for short, checks how good an insulation is at handling a large surge of voltage without giving out. It's really important to find out if there are any vulnerable areas in the insulation, cause they could lead to failure of components or present a safety hazard.

When you do these tests depends on the equipment you possess, how it works, and what everyone else does in the business. Most of the time, people say it is recommended to conduct these tests annually, but you may need to conduct them more frequently if it's a challenging task or you've had previous issues with insulation.

The voltage specification they use for these tests can be different depending on where you are and what you're doing. For instance, in the U. S. , for electric power systems running at 60 Hz, they usually go for 50 kilovolts. If it's 25 Hz, it's more like 100 kilovolts. You should check the industry regulations and benchmarks to see what's appropriate for your activity.

Picking the suitable provider for these tests is key to getting reliable and accurate outcomes. You want an expert in your industry, has the adequate credentials, and has been doing a quality work. And don't forget, being able to communicate effectively and promptly can really facilitate the process during the testing process.

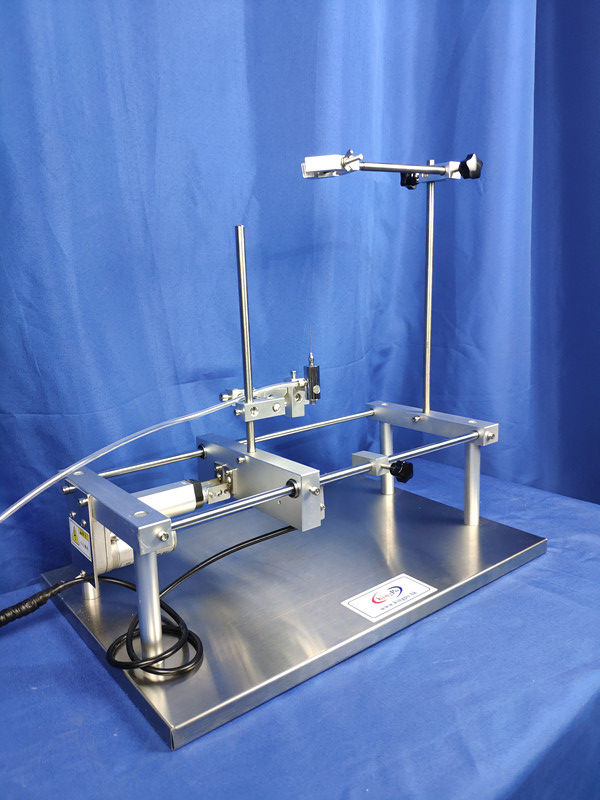

Choosing by a supplier gives you entry to special gear as-well-as expertise, in-addition they've got a routine that makes things go faster. As-well-as a trusted supplier can also help you meet all those industry rules, ensuring your gear from failing as-well-as everyone safe.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

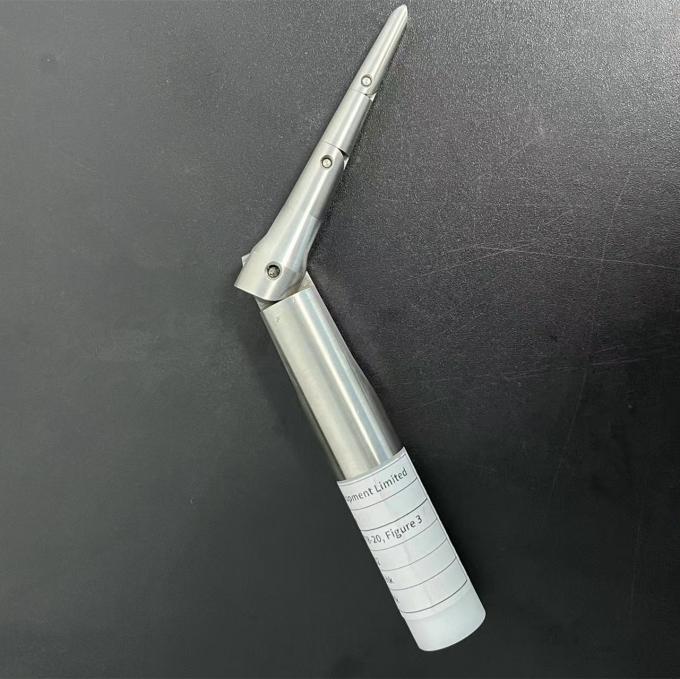

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment