How Impulse Tests Reveal Transformer's True Strength

Impulse tests are performed on transformers company to ensure their dependability and security. Such exams are super important in the energy competition, where transformers help to either raise or lower the electric potential difference. Alright, Come on Explore five major subjects all regarding these fundamental tests.

Number one, the importance of these impulse tests.

Number two, the different kinds of impulse tests.

Number three, the standards for doing these impulse tests.

Number four, the challenges we face when we do these tests.

Number five, the good stuff these tests bring.

Stress tests are like a preliminary test for the toughest stuff transformers could ever go through. We perform these tests to detect subtle issues that may not be evident in routine inspections.

Like, say a transformer might ace all its regular tests but still fail under an impulse voltage, and that's a indication of an unobserved issue. That's why these tests are a importance for making sure the transformer lasts and stays safe.

There are mainly two types of these tests: the single impulsive test and the repeated impulsive test. The single impulsive test is like administering a single strong shock to the transformer, like a lightning strike or power spike.

Now, the repeated impulsive test is more about giving the transformer numerous rapid impacts to see if it can withstand the repeated stress. Both of these tests are key for finding problems before they cause a major problem.

These assessment criteria can differ based on where you are and what kind of transformer it is. For instance, the the IEC has established some standards for these tests that a lot of people around the world use.

These standards make sure the transformers get tested in an equitable and precise manner, giving us certainty in their performance they'll operate securely and reliably. Following these standards is of significant importance for transformers that are used in crucial applications like electricity distribution and power transmission.

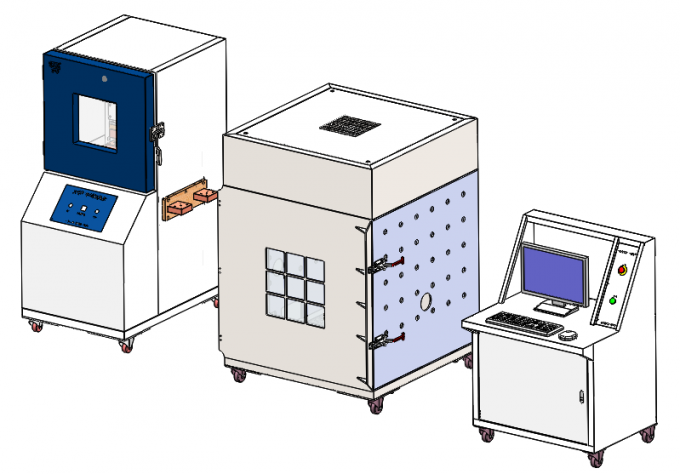

Doing these tests can be a daunting task because they involve really vast voltages and some sophisticated equipment. Safety's the highest concern because should an error occur, it can severely injure or or possibly result in someone's death.

Additionally, you have to be an expert to understand what the test results indicate. Even though if a transformer passes, it could still have problems. And failure does not always indicate it is unsafe. Therefore, we require experts to conduct these tests.

Although it is challenging, these tests offer many advantages. They assist us in detect issues at an early stage, which implies that we can prevent costly repairs in the future.

And it ensures the transformers are secure, providing peace of mind for both manufacturers and users. For example, a transformer which passes the tests will probably work really well out there, reducing downtime and maintenance expenses.

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment