Revolutionizing Transformer Safety: The Impulse Voltage Withstand Test Insights

Therefore, when we're talking about ensuring the safety and relicapacity of electrical the transformer, the surge voltage test is a really very important. The examination decides if a transformer is capable of dealing with short-duration, high-voltage surges that might happen because of electrical strikes or switch operations. Here are key information that we should understand about the crucial examination and How do it's making electrical the transformer safer in the future.

Why do we do this impulse voltage test on transformers, anyway?

So, how do they actually do this impulse voltage test?

What are they actually measuring during this test?

Why might transformers fail this test?

How do we use what we learn from this test to make transformers better and easier to take care of?

The main goal of this test is to ensure transformers can handle abrupt increases in voltage without any problems. Transformers are made to subject transformers to these simulated high-voltage surges to ensure their dielectric materials can handle it without producing any arcs that could compromise the transformer or result in an incident.

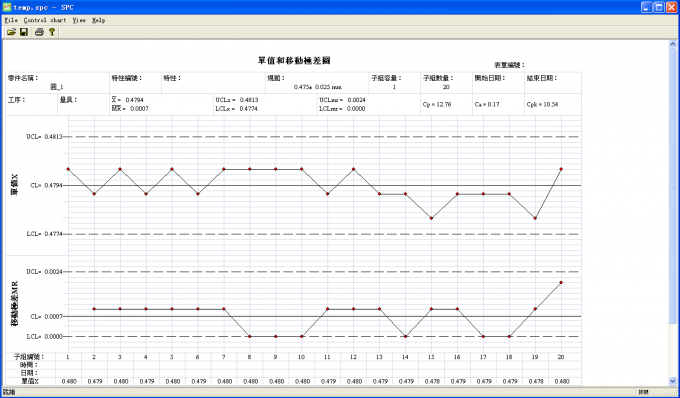

They utilize this specialized device called an impulse generator to generate a voltage waveform that looks just like lightning. After that, they connect the transformer to the generator, and they pass this wave through the transformer's coils. They assess the transformer's insulation resistance prior to and subsequent to they subject it to the surge, and they search for indications of damage.

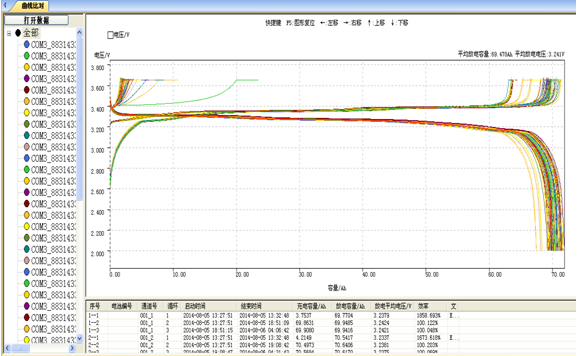

They measure a few things during the test, like how well the transformer isolates, its insulation integrity, and any partial discharge event. This helps engineers verify if the transformer is capable of withstanding voltage surges and find any weak points in its insulation.

There are a few reasons why a transformer might fail this test, like inferior insulation, production errors, or even the climatic factors. Sometimes, it's a merged factors that causes the transformer to fail. Finding out why it failed is key to keeping the transformer reliability and fixing any potential issues ahead.

The the test shows a lot about how how effective the insulation of the transformer is. By analyzing the findings, designers can identify issues they can improve the transformer's internal construction and how its maintenance. This means we can ultimately have long-lasting units and perform more efficiently in the electric network.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- ISO 80369-7 Luer Gauge Checklist

- ISO 594 is replaced with ISO 80369

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability