Call for Transformer Impulse Testing Mastery

Alright, so I'm into maintenance of transformers and I totally dig that whole Surge procedureing thing. Surge procedureing for transformers is super important - it keeps the electric systems safe and reliable. I'm going to dive into this whole Surge procedureing deal and examine some associated terms and how they're used in the actual world.

Surge procedureing is this nifty procedure that doesn't damage anything, and it checks the insulation of the transformer to make sure it is ready. They apply a shock to the transformer's winding with a high-voltage shock and then determine the current and voltage to obtain the result.

This test is great 'cause it spots potential problems with the insulation that might cause damage to the transformer and compromise its safety. From my experience, a good, thorough surge test is a very important – it really reduces the risk of transformer failures out there.

Transformer fluid is a key player in surge testing. It insulates the winding and assists in maintaining cool temperatures during the test.

I've worked with all sorts of Transformer fluid over the years, and I've learned that the stuff's quality can totally mess with the results. You really need to monitor and maintain that Transformer fluid so you achieve accurate test results.

You can't do those surge tests without the right high-voltage equipment, like generators and various wires and components.

My team and I always stress the importance of using dependable equipment and maintaining it to prevent spills and achieve accurate results. You've gotta get the gear perfectly and keep it up to date to ensure you hit the target with shock testing.

Transformer upkeep is key to keeping things operating efficiently and relying on electrical infrastructure for a long time. I've learned through the years that routine inspections, including that shock test procedures, help reduce downtime and service costs. Being preemptive with the Transformer upkeep game helps us avoid expensive repairs and keeps the equipment with extended lifespan.

So, to to conclude, shock testing for transformers is really important and needs considerable planning and care to perform correctly. Understanding these concepts and their functioning is a big deal – it helps ensure our power systems are secure and dependable. For additional information about this subject, I recommend the recommended sources:

- Maintenance and Repair of Transformers by Author John G. Heywood

- Transformer Impulse Testing Method: Theoretical and Practical Aspects by A.

K. Ray and Author D. K. Ray

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

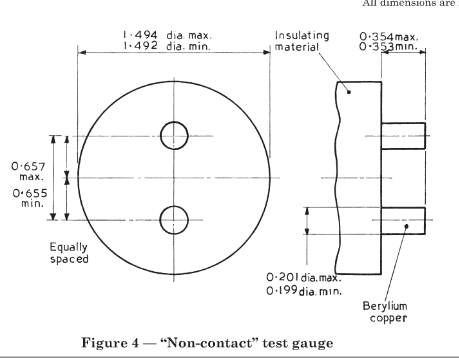

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment