Lightning Impulse Withstand Voltage Test Reviews

This lightning impulse voltage withstand test thing is super crucial in the electrical world. It's all about making sure our high-voltage equipment is safe and reliable. Hence they conducted the equipment throughout a lightning simulation, on determine whether it is capable of withstanding a heavy shock without failure.

Why's this lightning test stuff important anyway?

So, how do they actually run these tests?

So, what kind of problems do they run into while doing these tests?

How can we make these test results better?

Well, there's a few solid reasons why we do these lightning tests. First off, it can detect any vulnerable areas in the gear that might result in issues during a lightning strike.

And secondly, it makes sure our gear is up to snuff, following all the safety rules for everyone's protection. For instance, when I worked at a energy provider. We did these tests on our power transformers to make sure they could cope with lightning strikes without power cutoff.

The whole testing process is pretty simple: assembling the equipment, preparing the equipment, and then actually doing the test. The gear they use usually has a lightning machine and something that delivers a strong electrical shock.

They connect the equipment to the generator, and then they discharge it with a controlled lightning strike. After that, they inspect the outcomes to see if the gear can cope with the electrical pressure like it's supposed to.

One big trouble is that the test equipment can be really complex. The configuration can be super tricky, needing a pro to operate it.

Another hassle is getting findings that aren't correct, which can happen due to actions like climate or issues with the device. Like recently, at a study facility, we had a incorrect negative result because of a tiny trouble with the device, which got corrected later.

Well, there are a few methods to make the test findings better. First off, using excellent device is a must to get excellent, precise findings.

And secondly, technicians need to be well-trained to keep errors reduced. Plus, doing experiments in different conditions can give a better understanding of how the device operates. In my experience, we've seen the experiments get method better when we do these actions correct.

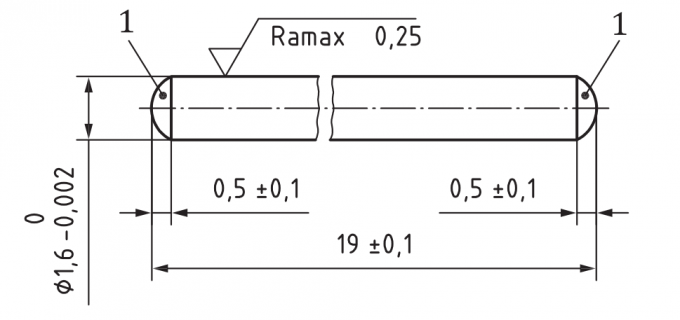

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

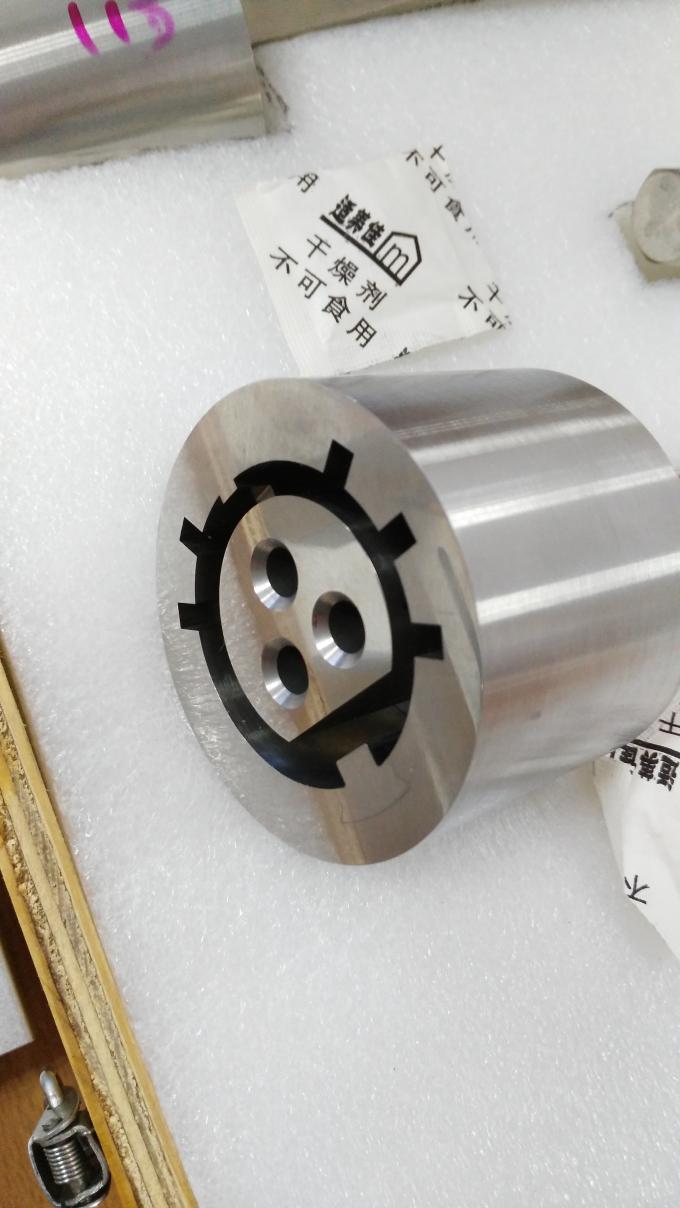

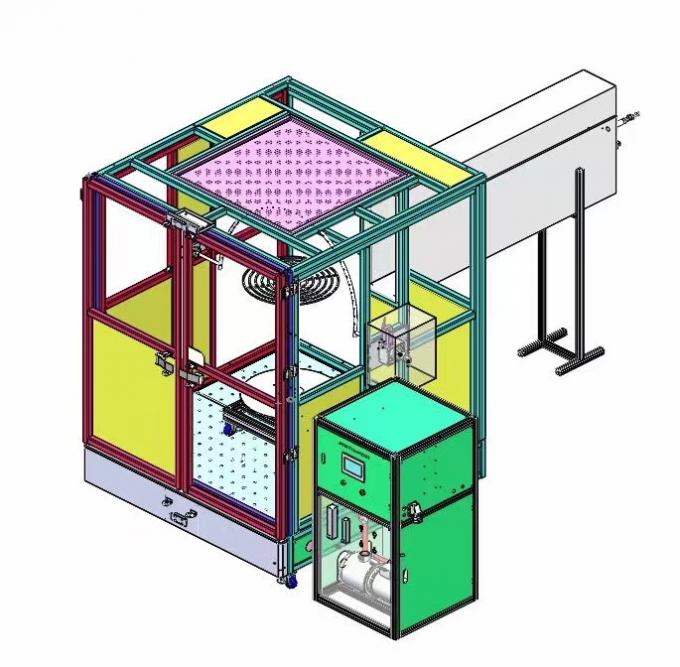

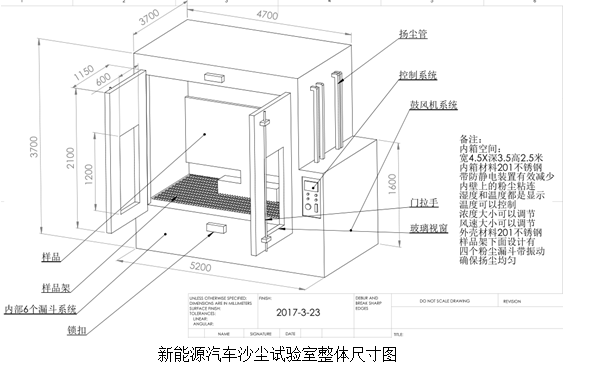

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit