Visit the World of Pressure Impulse Testing

Checking pressure sensors with pressure surges is super important for making sure they're super accurate and reliable. In the industrial automation and measurement game, pressure sensors are a big deal for keeping tabs on and managing pressure levels. This piece dives into the nitty-gritty of pressure surge testing, looks at the terms, and gives some real-life examples to make it more useful.

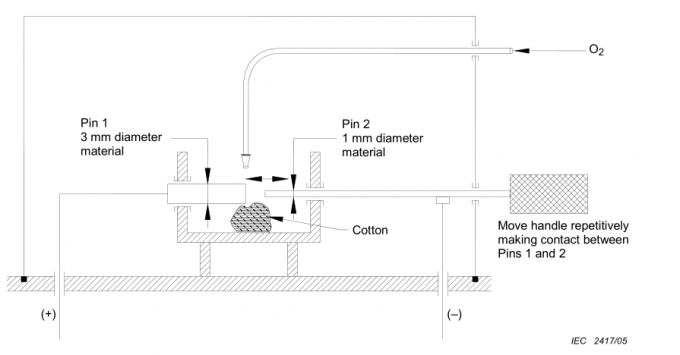

Pressure impulse is that sudden pressure fluctuation that happens when you force fluid into a valve or a bouncer. It's super important in industries such as oil and gas, where pressure shifts can mess up equipment or cause safety issues. Like, the API did a study and found out that pressure surges can really mess up pipeline systems, leading to expensive fixes and downtime.

A pressure sensor is device that converts pressure into an electrical signal. These sensors are extensively used in numerous applications, from the automotive to aerospace industries.

When testing a pressure sensor under a pressure surge, you must ensure it can detect those rapid pressure changes correctly. A survey by a company found that employing a high-quality pressure sensor can reduce product defects by 20%, since it can detect even minute pressure variations.

Pressure Testing is concerned with evaluating the quality and strength of pressure systems. You apply a pressure surge to the system and observe its response.

IPECA conducted a survey and discovered that performing regular pressure tests can reduce maintenance expenses by 15% throughout the system's lifespan. One of the advantages of pressure testing is that it can detect leaks or weak areas before they become significant issues.

Precision calibration is just adjusting the pressure sensor to make sure it gives you the right numbers. It's a significant matter for maintaining pressure sensors trustworthy in important applications.

NIST (National Institute of Standards and Technology) did a research and said that periodic calibration adjustment can make a pressure sensor last up to thirty percent longer. This calibration not just keeps it accurate but also assists in identifying any discrepancies, like when it gives inaccurate readings or retains outdated values.

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- ISO 594 is replaced with ISO 80369

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability