Mastering Impulse Pressure Testing: The Ultimate Guide

Inspecting components to ensure they are strong and function properly is extremely crucial, and that's what impulse pressure testing does. So, it's all about subjecting a substance or structure to a rapid and intense pressure, to observe its response when it's under considerable strain. We're gonna explore the details of impulse pressure testing, covering five critical components—like the process of performing it, its applications, and essential advice for getting it right.

Selecting appropriate materials is extremely crucial when you're doing this type of test. Typically, you opt for metals, polymers, and materials such as elastomers.

Each of these materials has its own unique characteristics that are best suited for varied applications. Metals are like superstars in pressurized conditions—they're resilient and durable. Plastics are pretty good at flexibility without fracture and withstanding potent chemicals, too. Additionally, remember rubber-based elastomers—they're great at withstanding impacts.

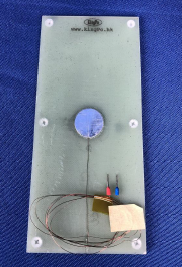

You gotta have high-quality testing equipment to perform this correctly. You'll usually find pressure meters, those converters, and high-pressure pumps in the mix.

Pressure meters help you measure the pressure while converters give you really precise readings. High-pressure pumps are all about creating that intense pressure surge. Additionally, remember to keep That equipment calibrated so you achieve accurate readings.

How you carry out the testing can vary depending on what you're testing and what its composition is. But here's the deal, you prepare the item, subject it to high-pressure treatment, and then record the outcomes.

Always adhere to the guidelines and the industry standards to ensure your findings are accurate. And Remember to maintain consistency and control to avoid dealing with external factors affecting your results.

This form of testing is widely used in various sectors such as aviation, cars, and the oil and gas industry. Within the aerospace industry, they utilize it to assess how components withstand intense pressure.

In the automotive sector, they conduct tests with it to examine the durability and robustness of auto parts. Furthermore, in the oil and gas sector, it ensures that pipelines and machinery are secure and dependable even under high pressure conditions.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- ISO 80369-7 Luer Gauge Checklist

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability