Revolutionizing Transformer Safety: Impulse Testing Insights

Alright, Have been working in electrical engineering for a extended period, and I've constantly been interested in how impulse tests operate. This is a significant matter regarding ensuring smooth operation of machines and for an extended period. Additionally, those in the field are very interested in it. Therefore today, I'm going to explore five very crucial elements of transformer impulse tests. I'll include some ideas and actual experiences to make it engaging.

First up, let's talk about why impulse testing is such a big deal.

Next, we'll explore the different kinds of impulse tests that are out there.

Then, we'll look at the gear needed to get the job done right.

After that, we'll go over the step-by-step process.

Finally, we'll see how impulse testing fits into regular maintenance.

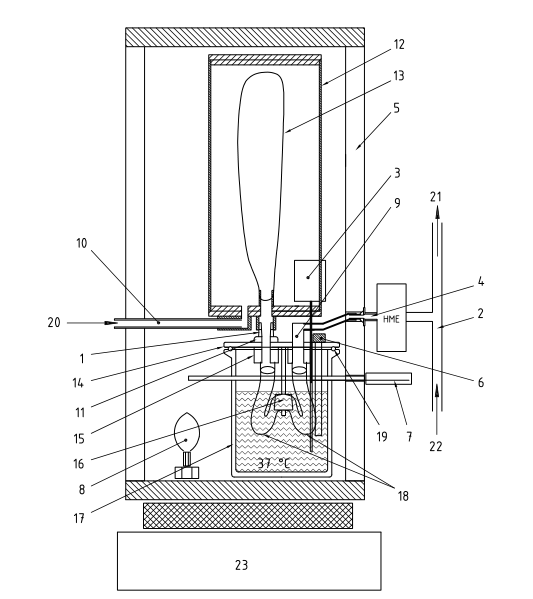

Surge testing is a secure method to inspect the interior of power transformers to ensure they're in proper condition. You basically apply a voltage surge to the power transformer with a voltage surge and observe the outcome.

This test identifies any vulnerabilities withwithwithwithwithin the insulation which could lead to the power transformer to fail in the future, which might be a major inconvenience. For example, there's this energy provider who informed me, 'we conduct these tests on a routine basis to ensure our power transformers are in good working order. It is crucial for keeping our electrical grid reliable. '

There are mainly two kinds of these examinations. One is referred to as the conventional impulse test, and the other one is the fast-reversal test. The standard test is the most common one. It's all about examineing the transformer's ability to sustain against the shock.

And the other one test is the fast-reversal test. That one examines how effectively the transformer can deal with indicationificant voltage fluctuations. Like this transformer manufacturer told me, 'Doing both examinations helped us detect issues early and make sure the transformer remains functional. '

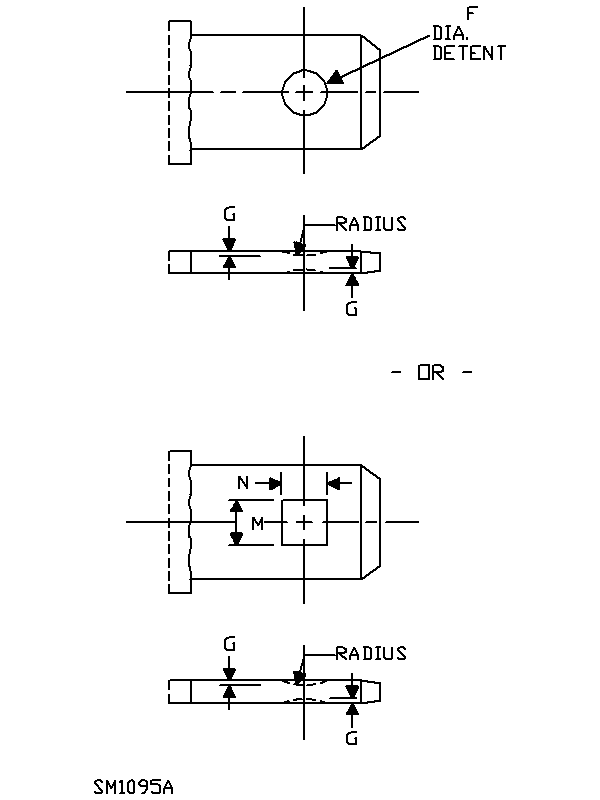

The gear you use to do impulse testing is just as important as the test itself. You need high-voltage devices and things that monitor current to do this right.

This large equipment manufacturer I talked to said, 'Our gear makes sure the results are extremely accurate. It's a indication of how quality of our products are. '

Testing method can change depending on transformer's design and what you're trying to find. You gotta abide by the regulations from the manufacturers and what everyone else does in the industry to get the desired outcomes.

A utility company informed, 'We've got a rigorous testing procedure these transformers. It's mainly focused on ensuring safety and dependability for our utility grid. '

Impulse testing it's not merely a one-off thing. It's a essential element of keeping healthy transformers. Consistent testing implies you catch problems early before they turn into big financial drawbacks.

This maintenance provider commented, 'We've observed the benefits of regular testing can keep transformers with extended life and reduce expenses. It's a favorable arrangement for our clients. '

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Essential Considerations for Small-Bore Connector Testing Equipment