Why Impulse Winding Testing Matters in Practice

Electricians totally rely on impulse winding testing, primarily used for evaluating the quality of machine windings. The whole point of this test is to find defects in the winding that could mess up the device functionality. We will explore major questions about impulse winding testing. We'll mix in some real-world experience with professional know-how to provide a comprehensive view of this important process.

What's this 'impulse winding testing' everyone keeps talking about?

So, how do you actually do this impulse winding testing thing?

Why is this test so important for keeping motors running smoothly?

But wait, there are some tricky parts to this test, aren't there?

So, where can I learn more about this testing stuff?

Impulse winding testing, or the high-voltage test as it's also called, is a non-destructive test that verifies how motor windings prevent electricity from escaping. It requires the application of a high-voltage impulse to the winding for a brief period, measuring the current passing through it, and examining the outcomes to assess the winding's quality. This method test is crucial because it identifies any weaknesses in the insulation that might cause the motor to fail or have a short lifespan.

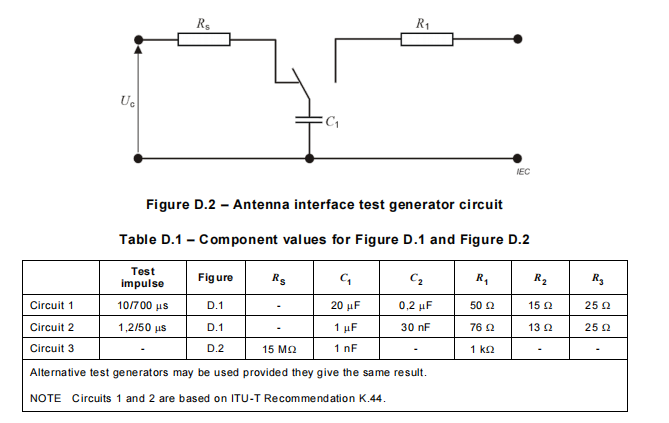

The process of impulse winding testing begins with motor winding connection to a generator of high-voltage impulse. The generator then produces a quick, high-voltage pulse, which is used on the winding.

You determine the current that zips through the winding with a unique device or resistor. Then, by looking at the way the current's pattern and how it soaks up energy, engineers can tell how good the insulation is. This test is typically conducted at a frequency of 50 or 60 Hz, depending on the motor's construction.

Motor dependability is huge in things like industrial equipment, vehicles, and aviation planes. Impulse winding testing makes sure the windings are in good condition so the motor continues to function correctly.

Early detection and rectification of these problems Reduces both your costs and inconveniences significantly, Additionally it ensures extending the life of the motor. Additionally, It assists in fulfilling the particularly stringent quality requirements that some industries, like aerospace and automotive, have.

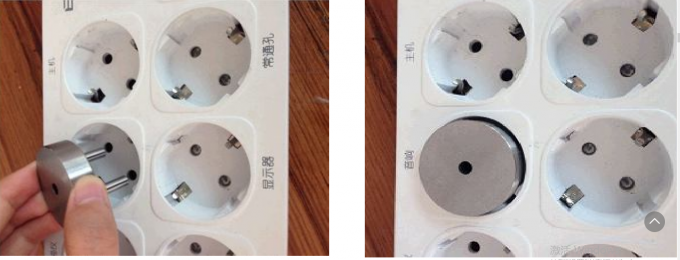

This kind of testing procedure is not straightforward. The first major difficulty lies in acquiring a device for producing high-voltage pulsed power which can produce the powerful pulse which is required.

Also, ensure that it everything properly configured thus avoiding any damage to the motor or test equipment. Additionally, which is required confirm that exactly accurate, otherwise you misinterpretation may result regarding the windings quality assessment. Understanding what the test’s insights mean can become complex. Which is required understand the how the testing process operates to comprehend the layout or composition of the motor.

If you want to get into the nitty-gritty of impulse winding testing, there's a bunch of web resources out there. Check out sites like IEEE eXpress, International Society of Automation, and National Instruments Corporation for loads of data. And if you need Thereforeme personal support, talking to a expert in electric engineering can be a considerable assistance.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability