Why Impulse Testing is Essential in Electrical Equipment

What is the purpose of conducting those electrical zap tests? The main goal is to ensure the safety, reliability, and longevity of our power equipment. Hence, Voltage spike testing is a significant process. It determines whether our devices can withstand rapid, high-voltage spikes. Below are five main points which explore the rationale for this crucial testing process.

2. Ensuring Equipment Reliability

3. Compliance with Safety Standards

4. Enhancing Equipment Longevity

5. Preventing Equipment Damage

A main reason for surge testing is to safeguard electrical devices against power spikes. These surges can be caused by thunderstorms, power line disturbances, or other power fluctuations. When we put our gear through the high-voltage zap, it's like testing how tough it is. We want to make sure it won't fail or damage anything when it occurs in practice.

Like when I had a friend's computer catch fire from a power surge. If it had been protected against those surges, it might have survived instead of getting smoked. That really drives home why power surge protection is so crucial in our electronics.

And don't forget, surge testing is key to ensuring our equipment is dependable. Stuff that meets the test indicates it can remain functional in challenging conditions, super important for keeping the manufacturing process. Regular testing can catch any issues early, saving us the problem of downtime and expensive fixes.

For example, in a manufacturing plant, a piece of machinery that withstands impulse testing can minimize the chance of production downtime because of equipment breakdown. That's a significant matter in industries where you cannot afford to halt, like pharmaceutical or food manufacturing.

Most of the time, these zaps are mandatory to meet safety rules. It's all about ensuring the safety of our equipment in different places and uses. When manufacturers undergo these tests, it shows their focus is on safety and they're complying with the regulations.

The NFPA conducted a research and found that equipment capable of withstanding such shocks has a 50% lower risk of ignition than untested equipment. It really drives home how important it is to meet safety standards with this kind of testing.

Frequent operation ensures the functionality of our equipment dependable and secure, plus it makes it last longer. It facilitates identify and resolve any vulnerabilities, making the equipment stronger and more robust.

I had a client who did frequent operation and saw their operation costs drop and the useful life of their equipment extended. It's a concrete case study of how this testing can extend the durability of equipment.

It avoids harm due to electrical fluctuations. By simulating those spikes, engineers can check how the gear handles them and make it better at dealing with them. It's a smart move that stops costly fixes down the line.

A energy provider I work with uses these tests in their operation. It's decrease equipment issues and improved the power network stability, showing how good testing can prevent damage.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

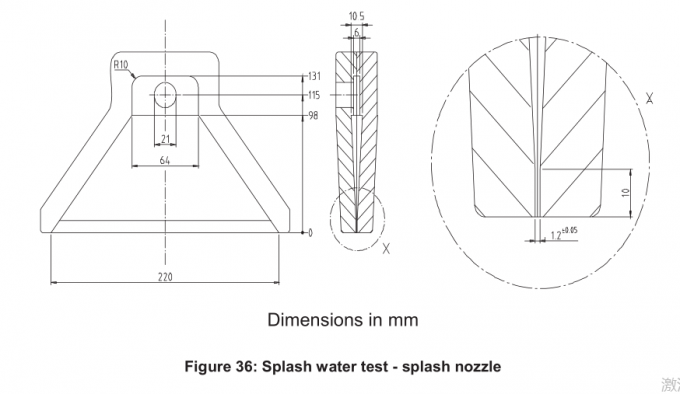

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability