Best Practices for High Voltage Impulse Testing

You know, testing power lines with voltage spikes is huge for keeping our power networks reliable and safe. Being in this industry, I've had the chance to see and participate in a lot of these voltage spike tests. So, in this article, I'm gonna share some of the knowledge I've gained and experienced, just focusing on the top five things we need to do for these tests.

1. Equipment Calibration and Maintenance

2. Test Protocols and Procedures

3. Data Analysis and Interpretation

5. Compliance with Industry Standards

First things first, making sure the equipment is calibrated and maintained is huge in high-voltage tests. That means we have to check the impulse source, the oscillooscillooscilloscope, and all the other equipment regularly. Getting it right means the numbers are accurate, and keeping it up prevents any problems during major tests.

We also gotta have a comprehensive set of guidelines and procedure for testing, it's pretty key for high-voltage impulse testing. These protocols need to cover everything from connecting the equipment to reviewing the outcomes. Following the procedure ensures everything flows smoothly and consistently.

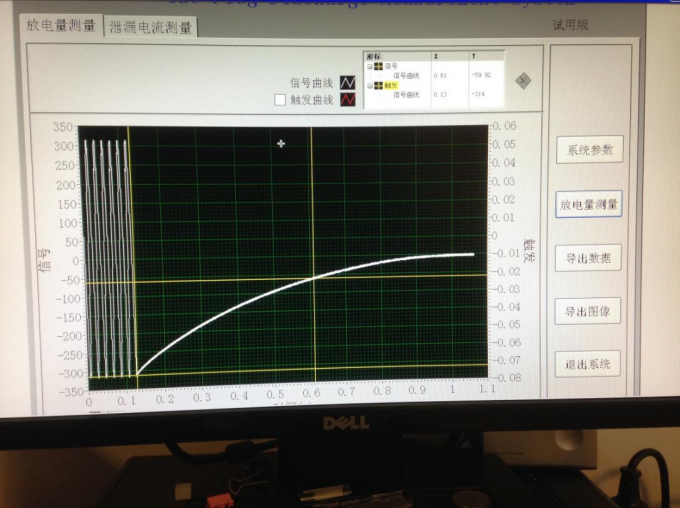

So, following the test, we gotta evaluate the information. We check out the oscillooscillooscilloscope traces, look for deviations, and figure out the integrity of the line. Ensuring accuracy in the measurements is super important for identifying issues early and making informed decisions on repairs.

Those exams might be dangerous, so securety must always come first. It's about complying with all the securety measures, donning the proper equipment, and ensuring everyone is well-informed.

We've got to make sure Those exams are Conforming to the industry regulations. This involves adhering to the procedures, using the correct equipment, and maintaining accurate records. Complying with the norms ensures our electrical grid reputable and secure.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment