Mastering Impulse Breakdown Voltage Test Procedures

Hey engineers! Have you ever needed to perform an impulse breakdown test on a high-voltage system? And you're not alone on this. It is extremely important for ensuring the safety and reliability of high-voltage systems. Therefore, in this article, I will discuss the main five points that you should understand about conducting these tests. I will provide you with some suggestions to aid you truly master it.

1. The Basics of Doing Impulse Breakdown Voltage Tests

2. Picking Out the Right Gear for the Job

3. Keeping Safe While You're Testing

4. Making Sense of the Test Results

5. Always Getting Better at the Test Process

Alright, let's rewind to In my early days. I can still recall upon my first learning of this thing called impulse breakdown testing.

It was quite challenging. The fundamentals are quite simple: you expose the material with a voltage surge and observe its failure point. It enables us to observe where the material may be susceptible to failure and makes sure it can hold up under high potential difference. You gotta grasp the fundamentals of the fundamentals of it to perform the test correctly.

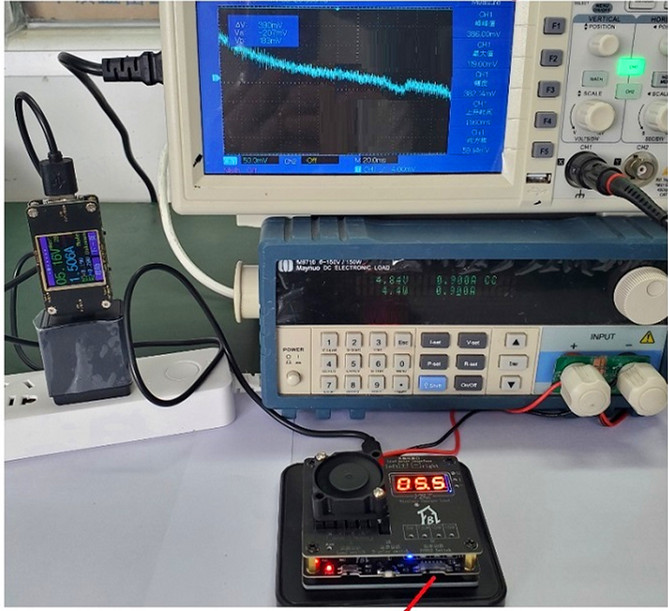

Ensuring the appropriate equipment is chosen is key to a good impulse breakdown test. I've seen numerous engineers get confused by this.

You gotta consider such as the voltage spectrum, rate of voltage rise, and the appearance of the pulse waveform. And the the system must to be able to record the disruption voltage fairly accurately. My colleagues and myself came up with some recommendations to help engineers select the most suitable equipment for their assignment.

Safety has to be your utmost priority when you're managing high-voltage items. I've had several near accidents, and believe me, it's not worth the danger.

You gotta Comply with safety guidelines, like wearing the right gear, grounding the arrangement, and making sure everyone knows what they're managing. My team put together a big safety manual covering everything about these tests.

Once the test is overing concludes, it's time to determine what the results mean. It can be tough, especially if you're new at this.

You really need to gain an understanding of what the failure voltage means and how it affects how the material withstands under high voltage. I've found that discussing with my team about what I've learned has really helped us become proficient at interpreting the test results right.

This entire electrical breakdown test thing is always developing. You've got to keep up with the new advancements and techniques.

My team and I are recognized for our work in this field, and we're always trying to go further. And by keeping our testing methods up-to-date, we make sure our clients get the highest possible outcomes.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

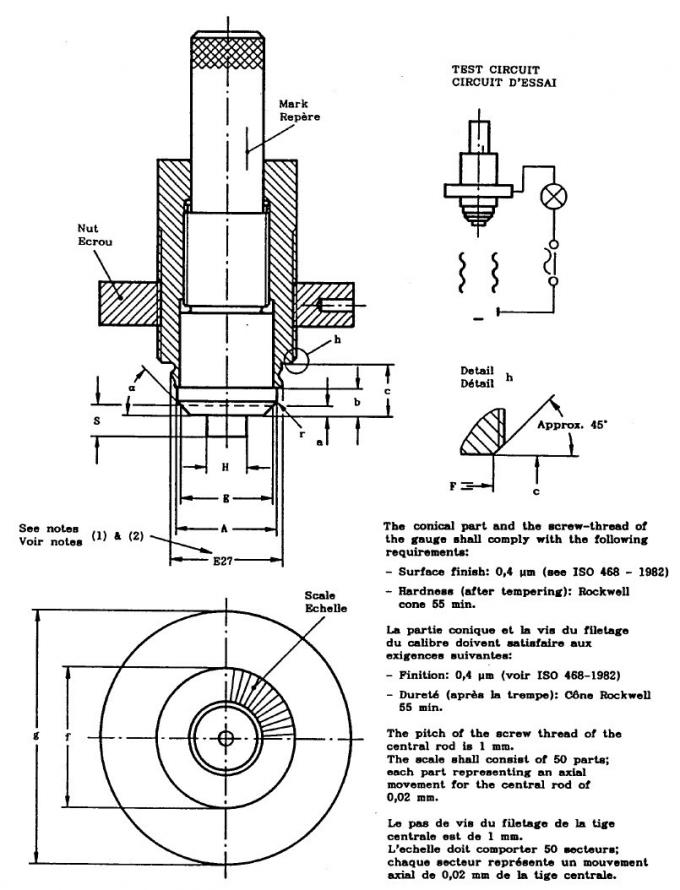

- ISO 80369-7 Luer Gauge Checklist

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

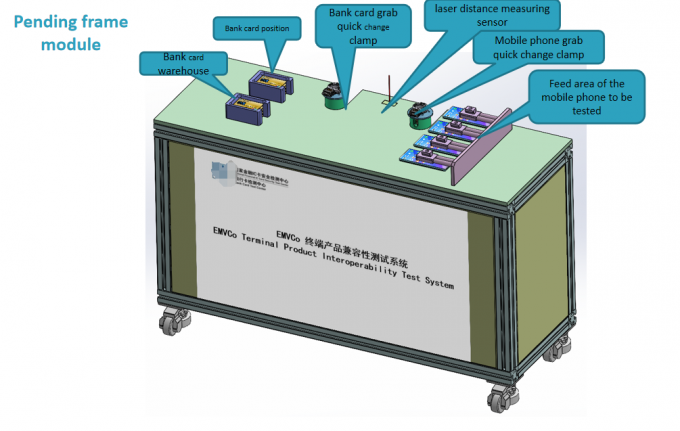

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment