Revolutionizing Structural Integrity: The Power of Vertical Head Impulse Test

Vertical Head Impulse Test, or the vertical head impulse test, is a significant development in structural engineering. Which is a non-harmful way to check how robustness of components and constructions are. This test thing is quite impressive—it provides high precision measurements. That's why it's extremely well-received across various sectors, from construction projects to manufacturing aircrafts.

1. The Evolution of Non-Destructive Testing (NDT)

2. Applications in Construction and Infrastructure

3. Advancements in Materials Testing

4. The Role of VHIT in Aerospace and Defense

5. User Experience and Success Stories

NDT has come a long way since its inception. From the early days of Radiographic Inspection to the arrival of acoustic emissions and ultrasonic inspection, the area has continuously evolved.

VHIT technique is like the king of tests, showing how far we've come and giving engineering professionals a quicker, cheaper way to do their jobs. VHIT technique uses some complex physics to find problems in materials before becoming a major issue.

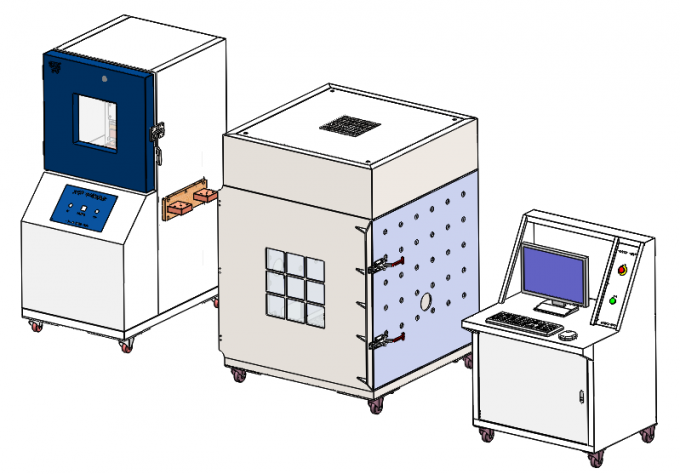

A key application of VHIT technique is in the construction sector. Whether it's assessing the structural soundness of bridges and structures, edifices and structures, or dam and structures, VHIT technique provides a non-invasive method to guarantee safety and dependability.

For instance, constructing a high-rise building—VHIT can monitor how these steel girders performing under stress. All of this means our facilities is more secure, and we're saving time and cash over the long term.

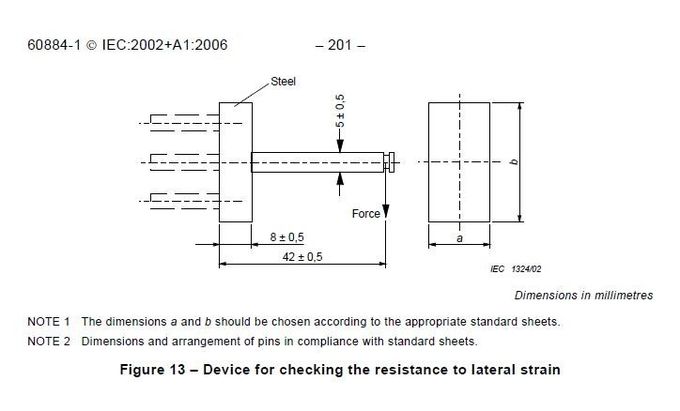

VHIT is also a game-changer when it comes to material assessment. When you put materials through a controlled shock, you can determine how robust and durable they are.

Figuring out the material's strength is essential for picking the right stuff and ensuring its longevity. VHIT has assisted in the testing of materials for aircraft, making them more agile and resilient.

VHIT is extremely crucial in aerospace and defense for ensuring the integrity of aircraft and spacecraft. VHIT helps engineers detect vulnerabilities and repair them before any issues arise. VHIT is performing excellently of reducing accidents and increasing the safety of these critical applications.

Organizations have already boarded the boat and seen VHIT do its thing. Like how one big construction firm used VHIT for inspecting a bridge and detected a fracture in the early stage—would have been a significant problem if they hadn't. Another success lies in aviation domain. VHIT identified an issue with the aircraft component, preventing a major catastrophe ahead of time.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- What are the key differences between ISO 80369-7 and ISO 594?

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 80369-3 Test Equipment LIst

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview